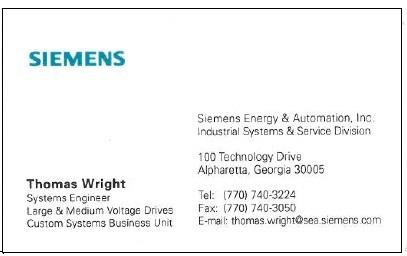

Siemens Energy and Automation

DIVISIONS

1. Custom Controls

2. Large and Medium Voltage drives

Various Contracts

Control Panel

Layout

Interim Project management. ECN's and ECOs on project changes. Created labor routings, assignments and labor time studies. Project management documentation. Coordination with production personnel and product engineers on product improvement, process improvement and error reduction. Production database normalization. Heavy customer contact on design and quality.B.O.M. development and ordering of parts through purchasing department. Q.A. check of incoming manufactured and stock parts. ISO 9001 procedure writing. Development of OEM manual for products

I AM SEEKING AN OPPORTUNITY TO BE MENTORED IN "CONTROL SELECTION, PLC PROGRAMMING AND OR HMI DEVELOPMENT". TO PERFORM THE TASK A FEW TIMES UNDER SUPERVISION, IN ORDER TO DEVELOP A "TECHNIQUE" AND BE MORE "COMPLETE" IN CONTROLS ENGINEERING. I'M NOT GOING TO LEAVE , QUIT OR EXPLOIT "YOUR HELP". MY DESIRE IS TO CREATE A LEGACY BEFORE I MOVE ON. BUT IF TREATED WELL AND FAIR GROWTH IN OPPORTUNITY AND SALARY - WHY WOULD I LEAVE?

I AM A QUICK LEARNER WITH SOME TRAINING IN (S7, WINCC, WONDERWARE) BUT NEVER HAD THE OPPORTUNITY TO PERFORM THESE TASKS DUE TO DEPARTMENT COMPARTMENTALIZATION OF THESE TASKS.

I AM A SELF STARTER WHO CAN ACHIEVE, BY JUST EXPOSURE TO TRAINING DOCUMENTATION FOR PROPER TECHNIQUES. WITH A LITTLE HELP AND SUPERVISION, IN A FEW CYCLES I WOULD BE INDEPENDENT AND A GREAT RETURN ON YOUR INVESTMENT.

I CAN ASSURE YOU I TYPICALLY MEET AND EXCEED EXPECTATIONS GRAPHICALLY AND PROGRAMATICALLY AS WELL. I SIMPLY SEEK THE OPPORTUNITY.