MY "DETRACTOR" DID ALL HE COULD TO EMBARRASS ME AND IMPLICATE ME, INTENDING TO BE OVER HEARD BY OUR MANAGER IN THE NEXT CUBICLE, IN ORDER TO SET THE STAGE FOR COMPLAINTS ON MY USEFULNESS AND INABILITY TO MAKE ANY THING BETTER THAN HIS DESIGNS. EVEN USING "PROFANITY". I WAITED FOR MY MANAGER TO INTERVENE. HE NEVER DID.

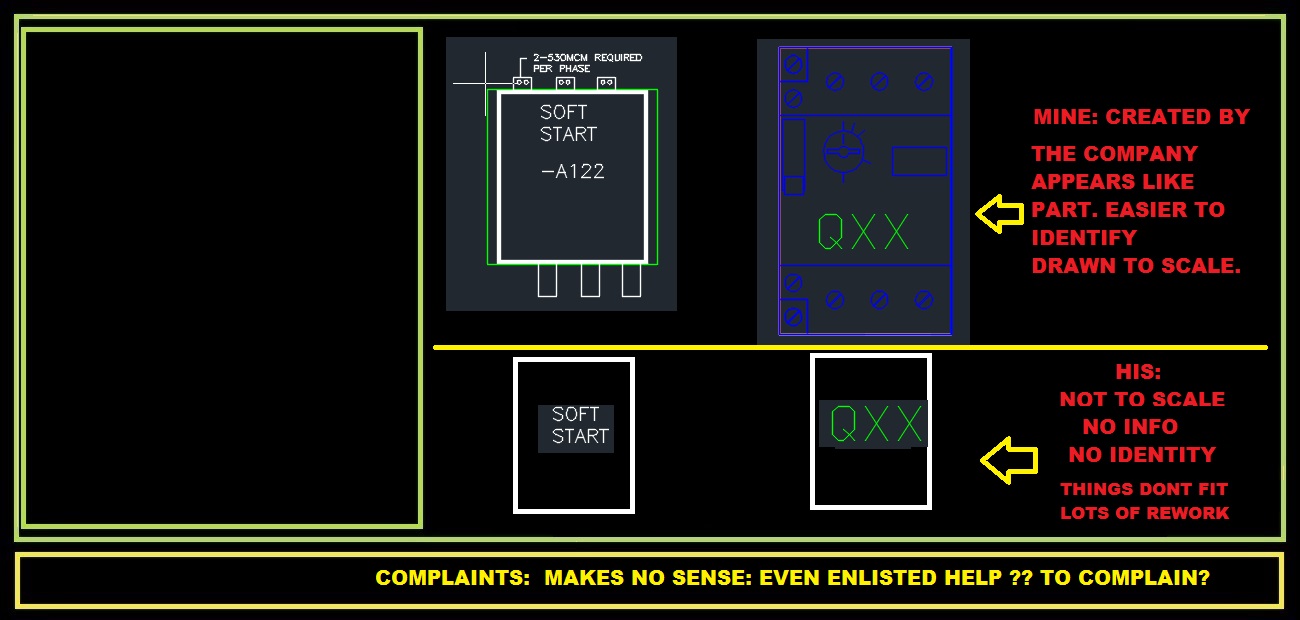

COMPLAINTS THEN BEGAN ON THE DETAILED NATURE OF MY LAYOUTS AND SYMBOLS-(ACTUALLY RECRUITING ANOTHER PERSON TO HELP COMPLAIN) WHEN THEY ACTUALLY CAME FROM THE "COMPANY", BUT WERE NEVER UTILIZED.

"NOW" ALL "ANYONE" USES AT THAT FACILITY (OR ANWHERE I KNOW OF): ARE "DETAILED IMAGES".

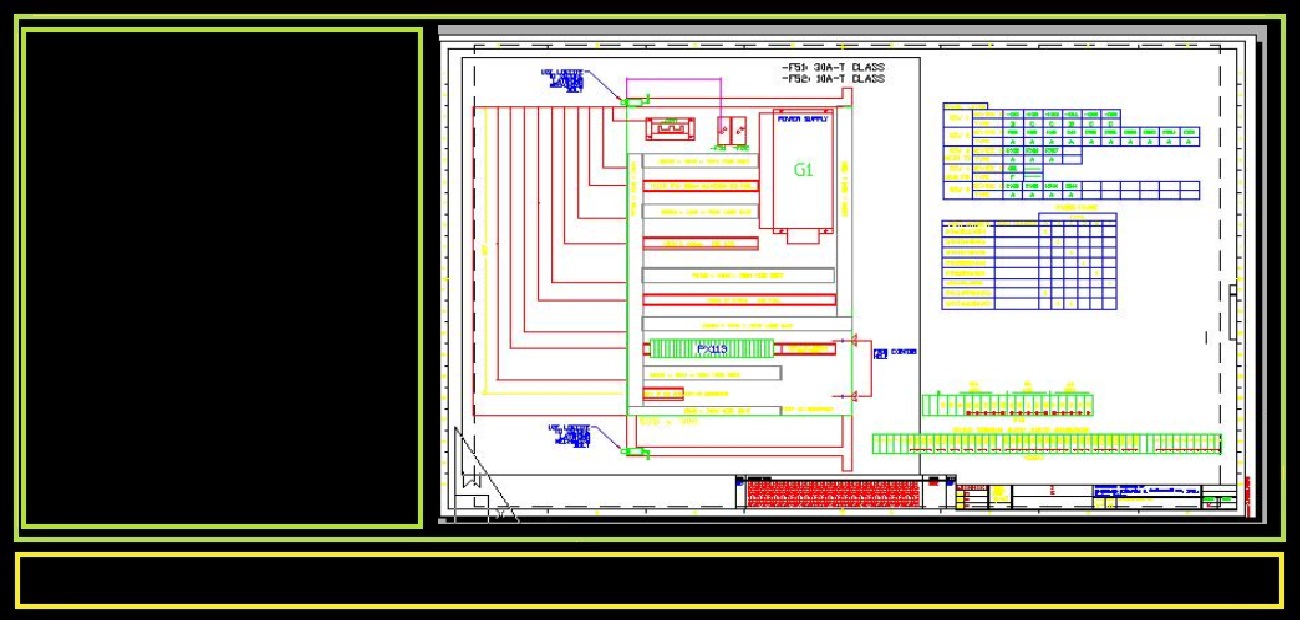

BY MAKING THINGS "MORE VISUAL" THEY NOW UNDERSTOOD THE DOCUMENTATION "BETTER" AND MADE LESS ERRORS AND THE TYPICAL REWORK FROM LACK OF UNDERSTANDING DIMINISHED. "ASSEMBLY" TEAMS BEGAN TO APPRECIATE MY CHANGES.

I AM "MILD MANNERED". I WAS NOT INCLINED TO "RAISE MY VOICE OR FIGHT BACK". I COULD SENSE THERE WAS NO INTEREST IN "EXCUSES". I SIMPLY CONTINUED MY EFFORTS. MY MANAGER DID NOT INTERVENE.

I SUPPORTED OTHER DEPARTMENTS AS THE CAD "GURU" OF SORTS ON PROCEDURE,PRINTING AND CONFIGURATION. THEY ALL HAD "FULL AUTOCAD". OTHER MANAGERS GOT TO KNOW ME, AS I HELPED THEIR TEAMS.

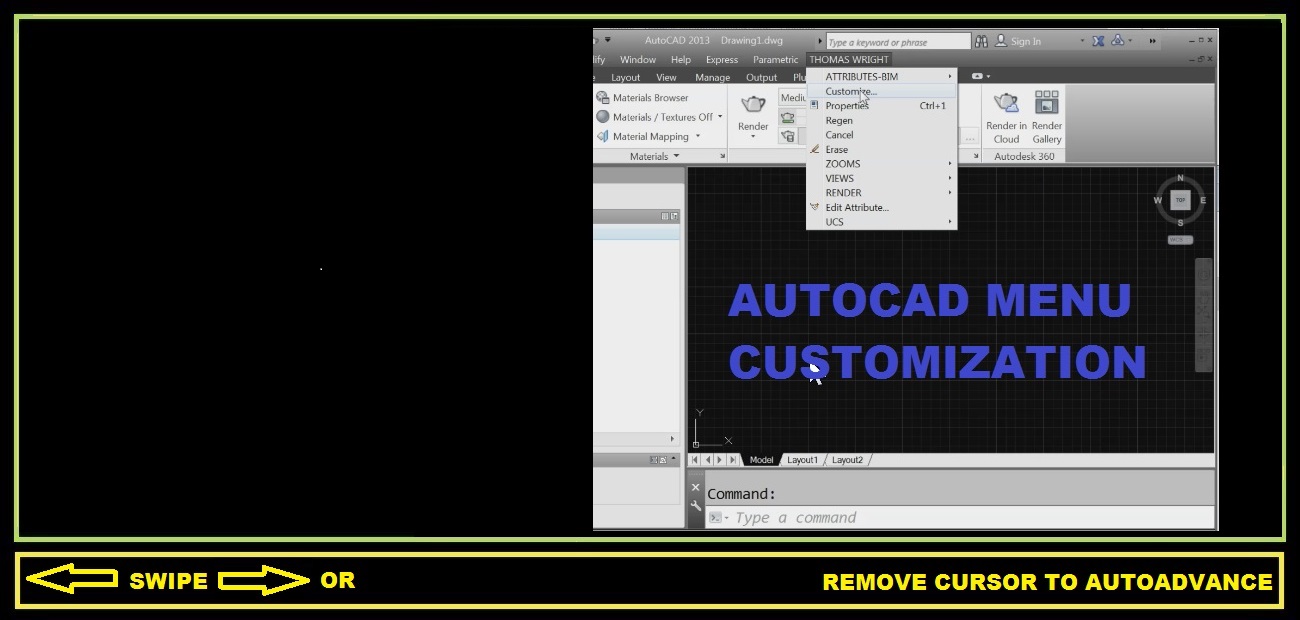

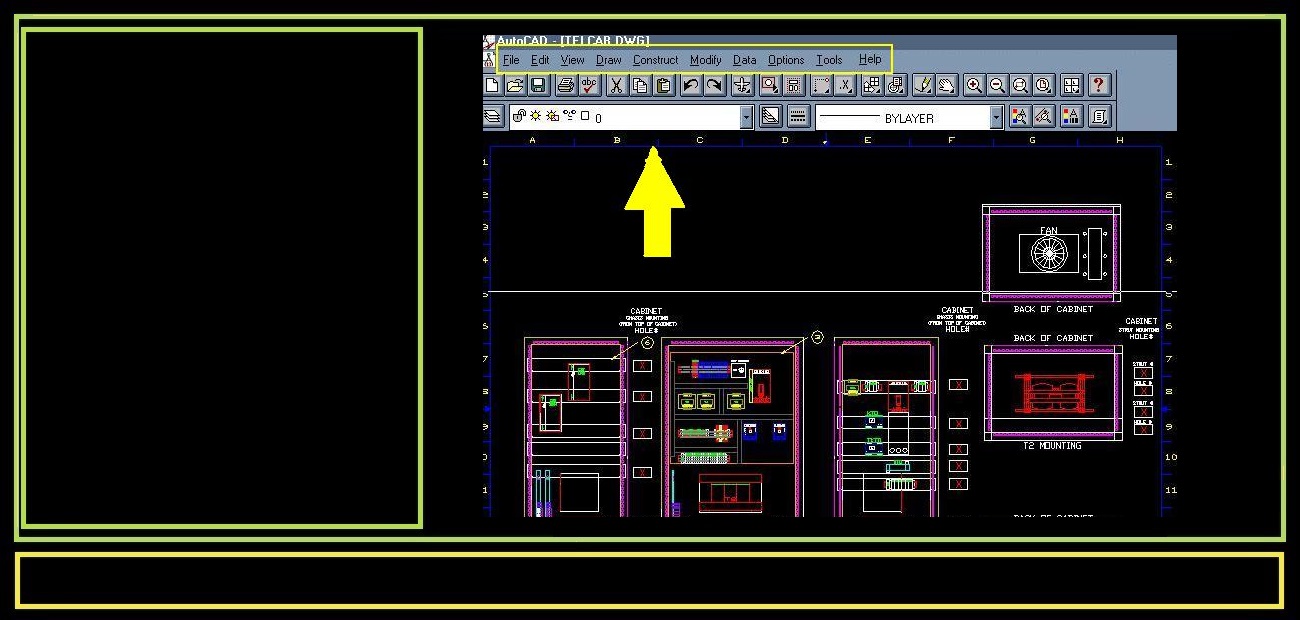

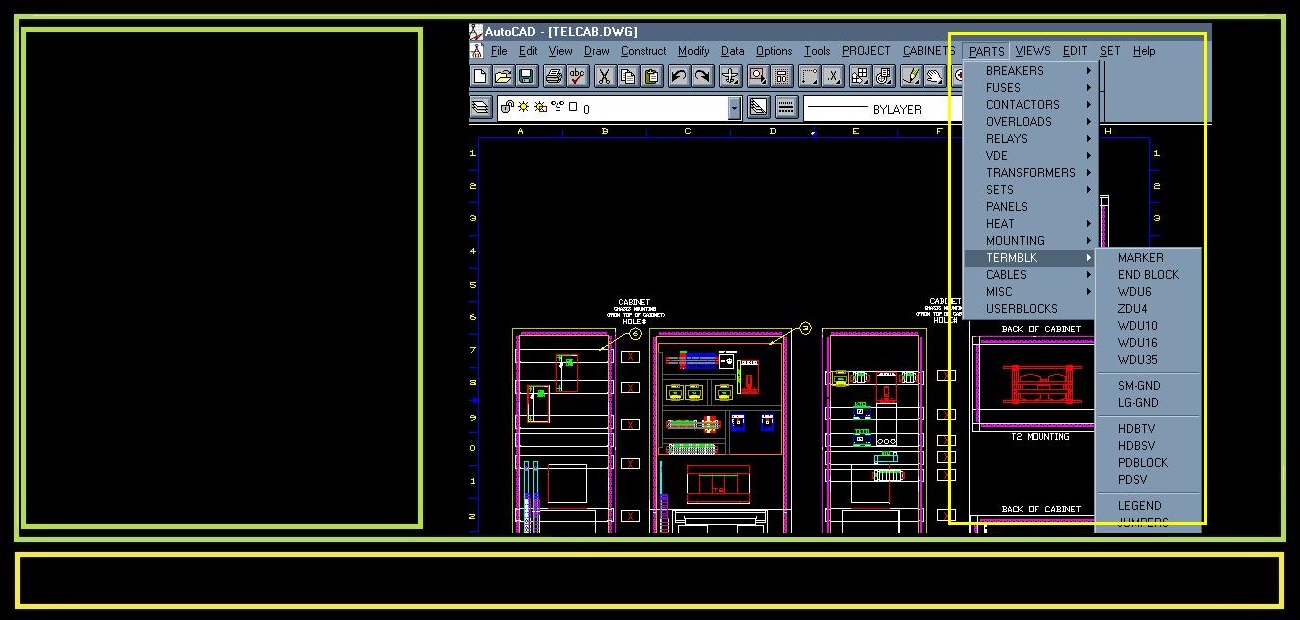

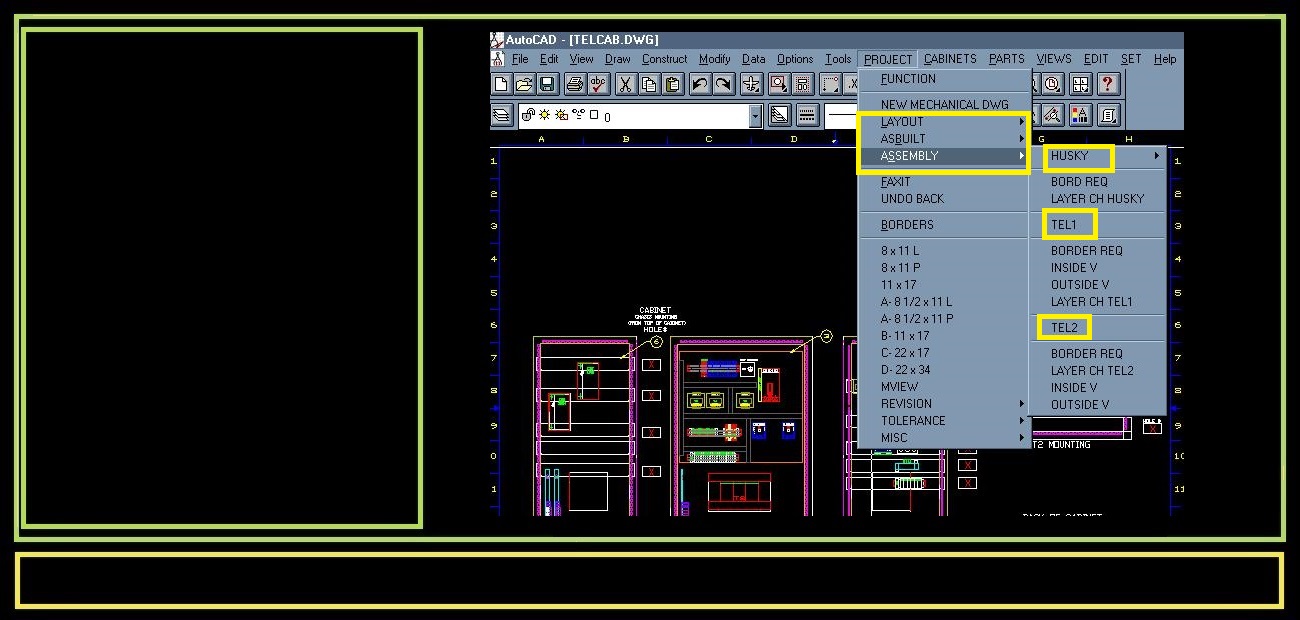

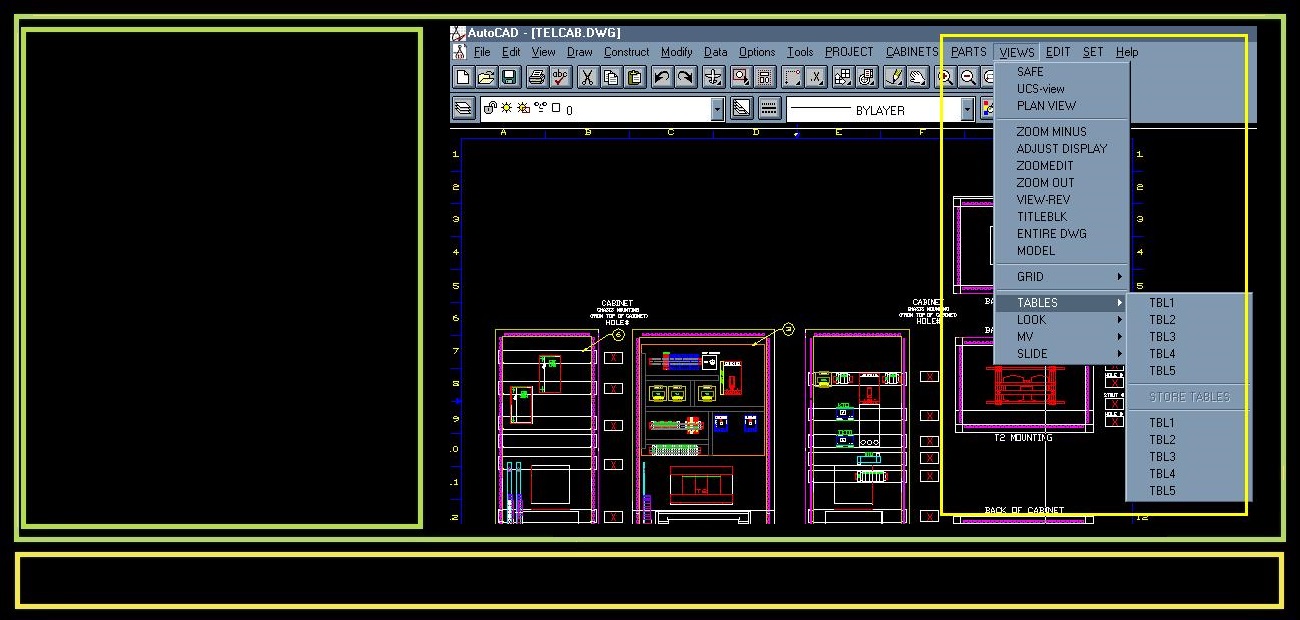

THE IMAGE ON THE RIGHT, SHOWS THE "STANDARD" 1993 AUTOCAD LT MENU SYSTEM.

MY ROLE WAS "ILL DEFINED" & I HAD "NO SUPPORT",SO I DECIDED TO WORK ON INCREASING "ACCURACY AND PRODUCTIVITY". OTHER DEPT. MANAGERS NOTICED ME COMING IN ON WEEKENDS AND OFFERED SUPPORT.

.

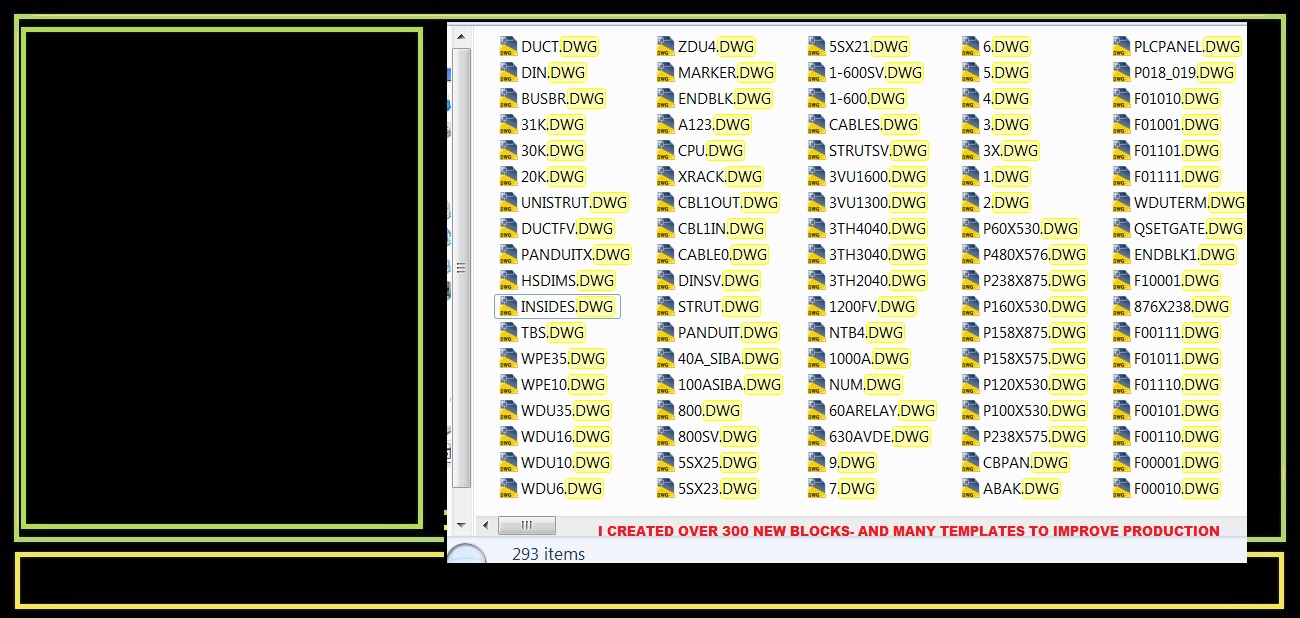

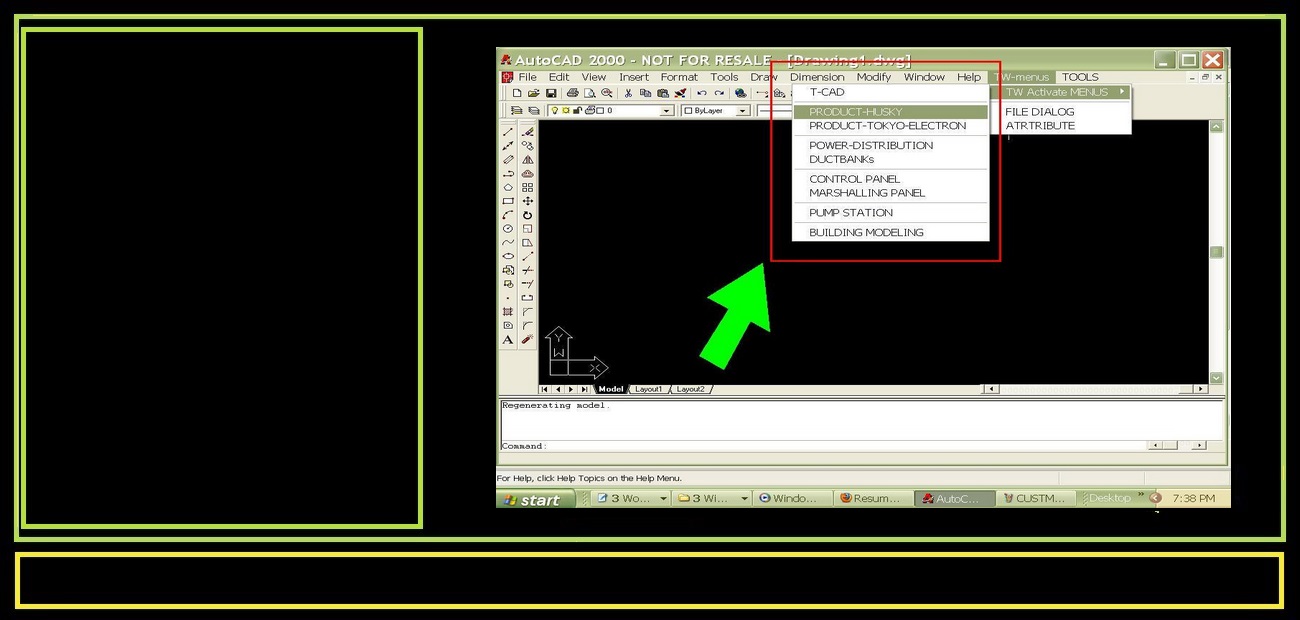

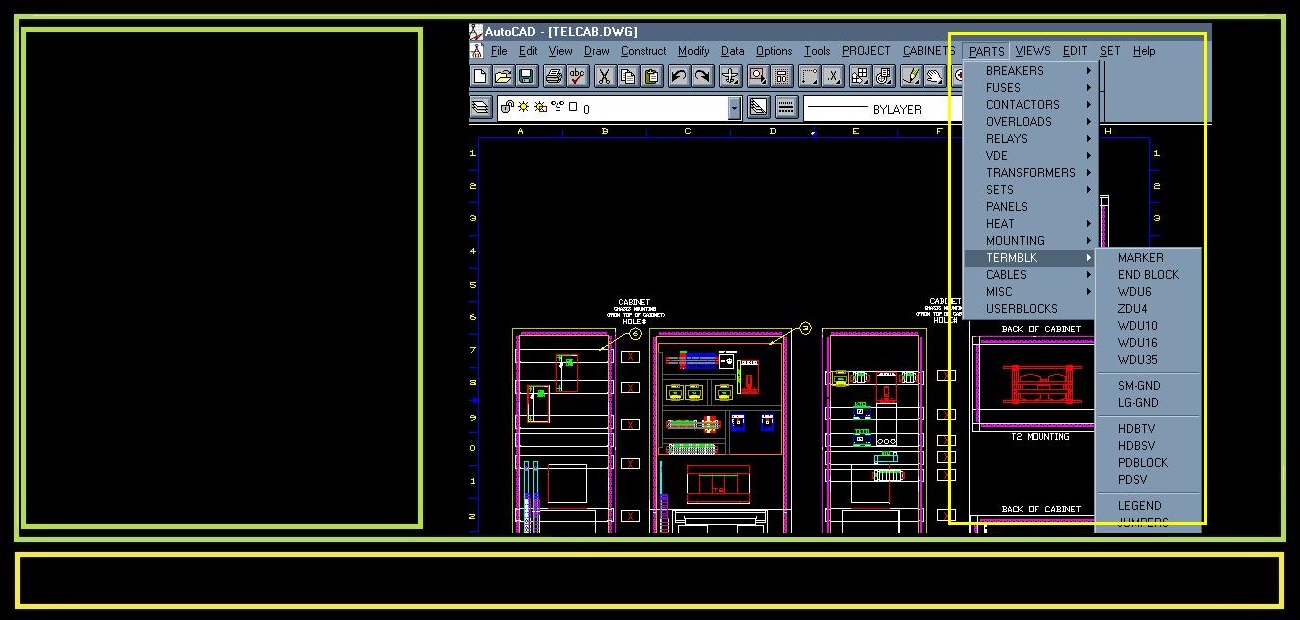

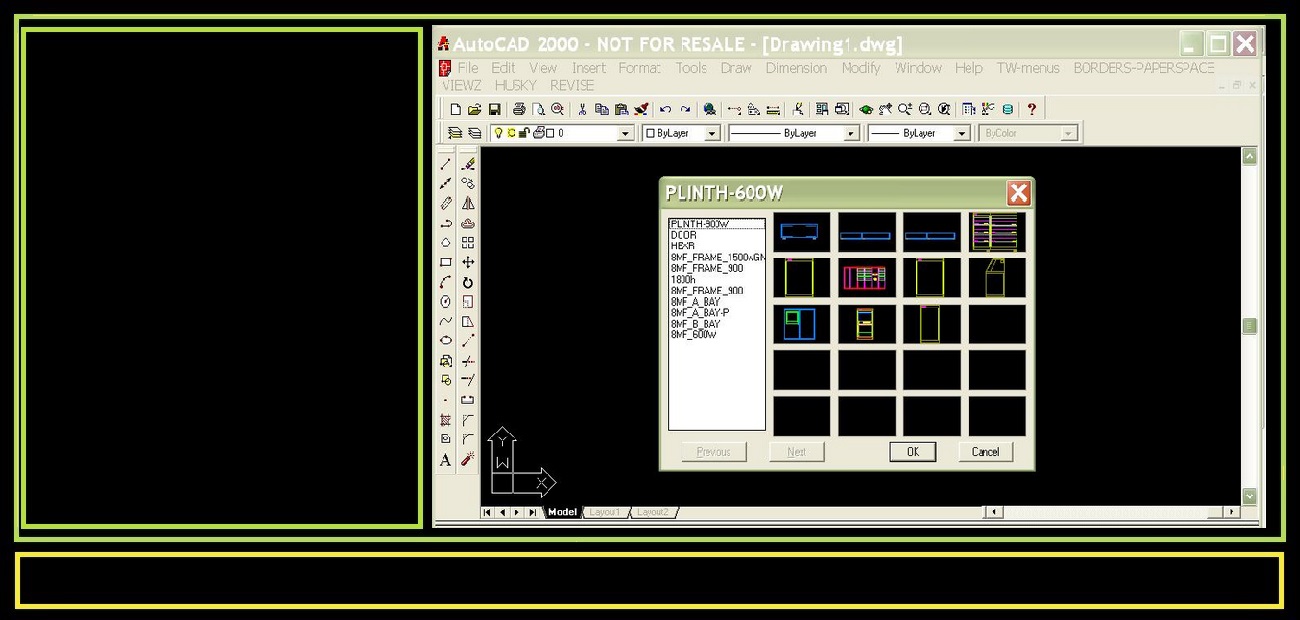

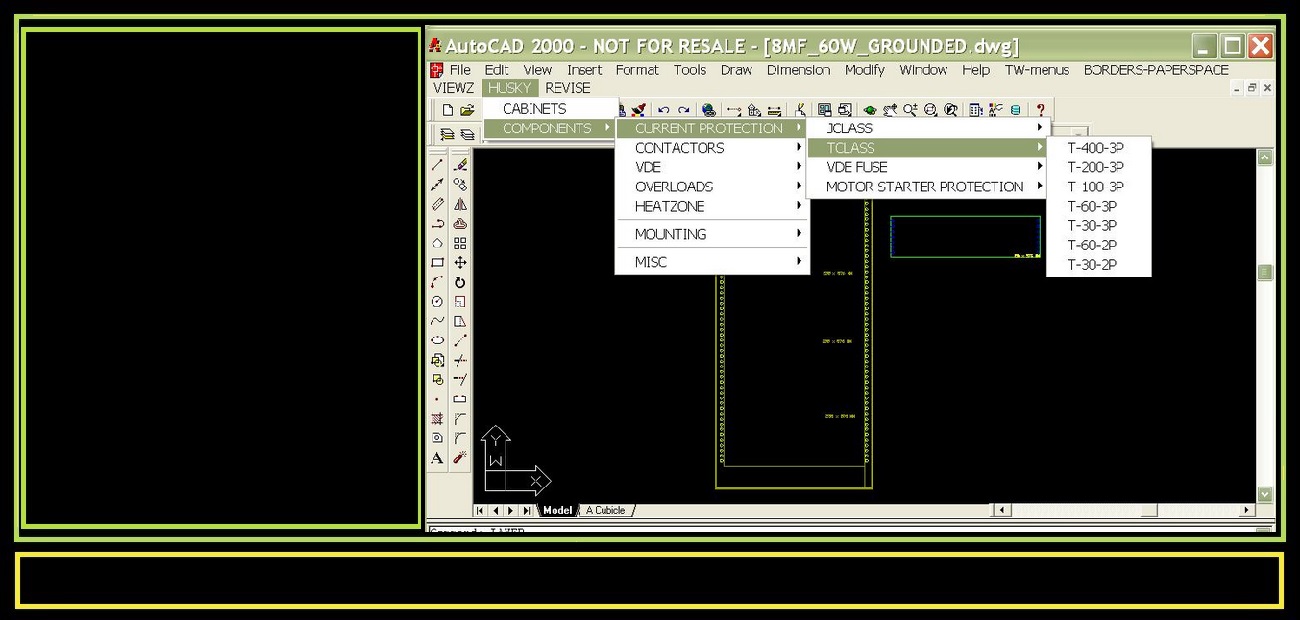

NOW THAT I HAD A SENSE OF DESIGN STANDARDIZATION, I THEN DESIGNED A NEW AUXILIARY SET OF "PULLDOWN MENUS" TO INCORPORATE THE PARTS,AND MIMIC THE NATURAL ORDER OF HOW I DESIGNED THE PRODUCT. THE 6 EXTRA MENUS (SEEN ON THE RIGHT) BROUGHT A SENSE OF "STANDARIZATION" TO THE DESIGN PROCESS.

THE "LOOK AND VOCAL ATTITUDE" WAS CLEAR. HE "DEMANDED" TO KNOW "WHAT I HAD DONE", "IF ANYTHING" TO CONTRIBUTE IN THE "LAST 90 DAYS".(IT WAS CLEAR HE WAS PREPARING TO "FIRE ME" SINCE THE ENGINEER HAD BEEN WORKING ON THIS "BY YELLING AND PROFANITY", MY ENTIRE 1ST 90 DAYS. (TEMP. TO PERM.)

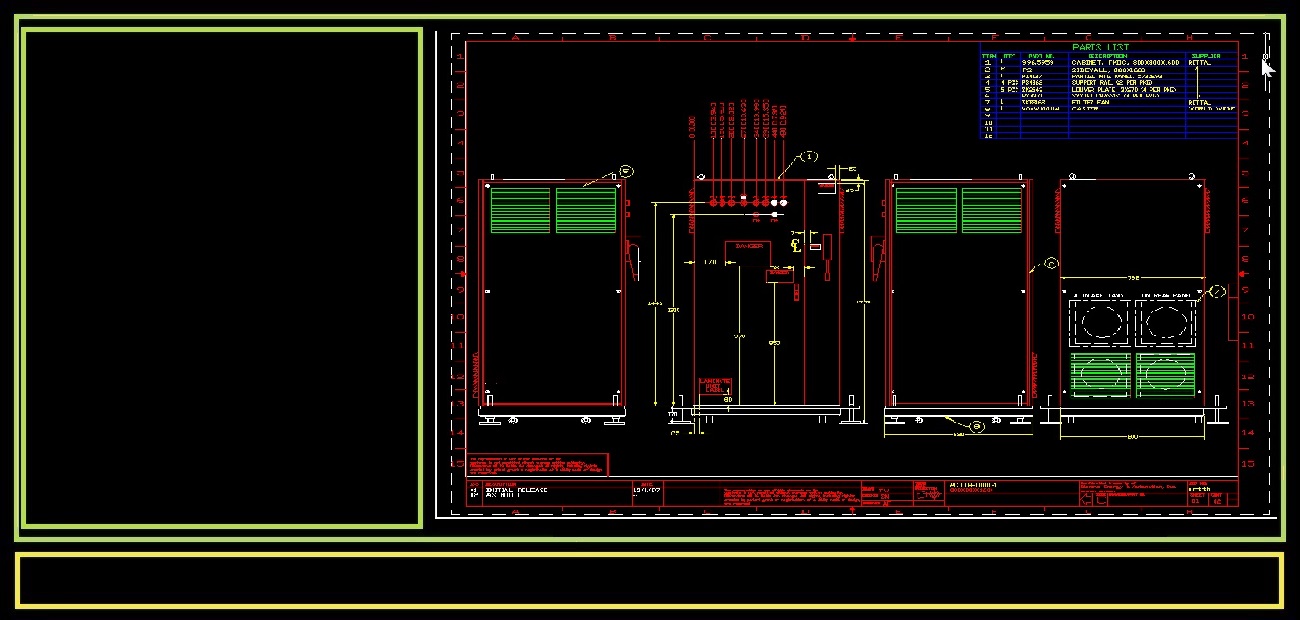

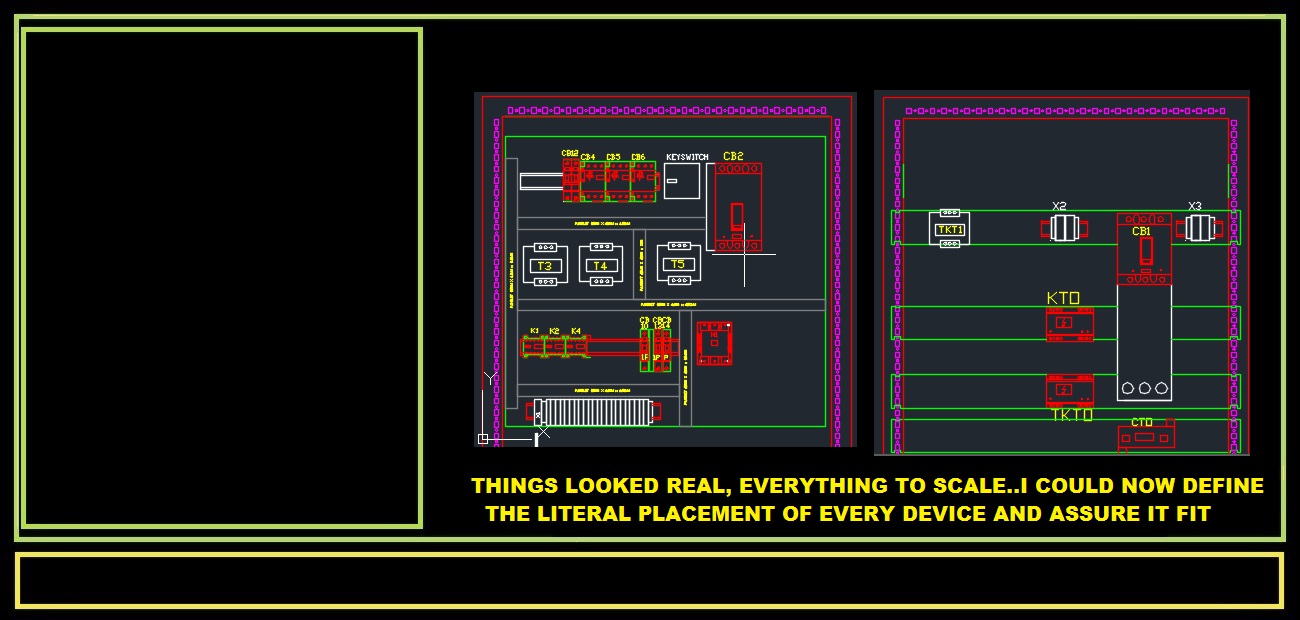

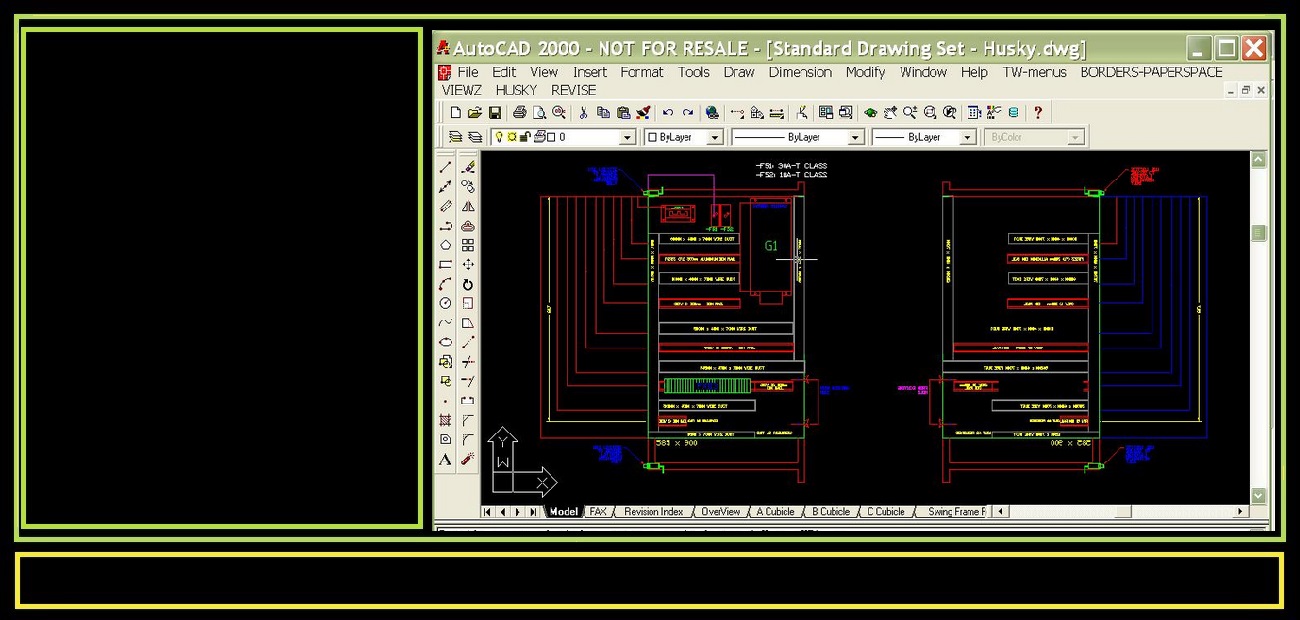

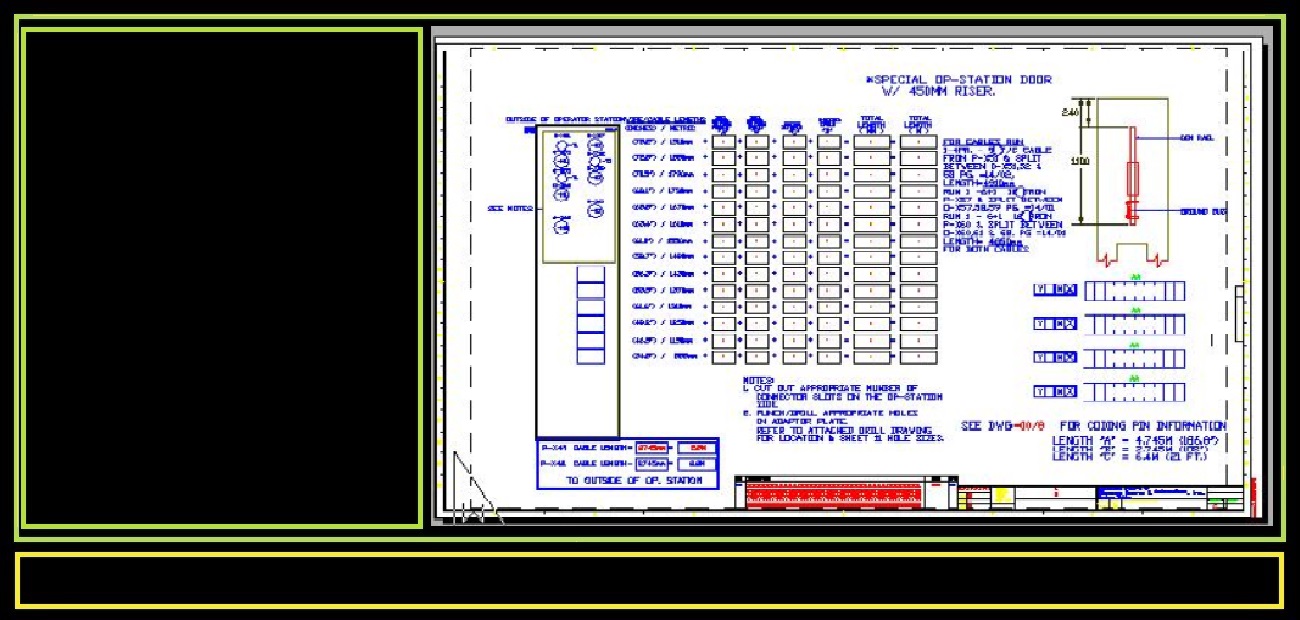

I INSERTED PARTS INTO THE DRAWING. EACH BLOCK PROMPTED FOR COMPONENT ID AND THE DEVICE DESCRIPTION WAS BUILT INTO THE BLOCK.

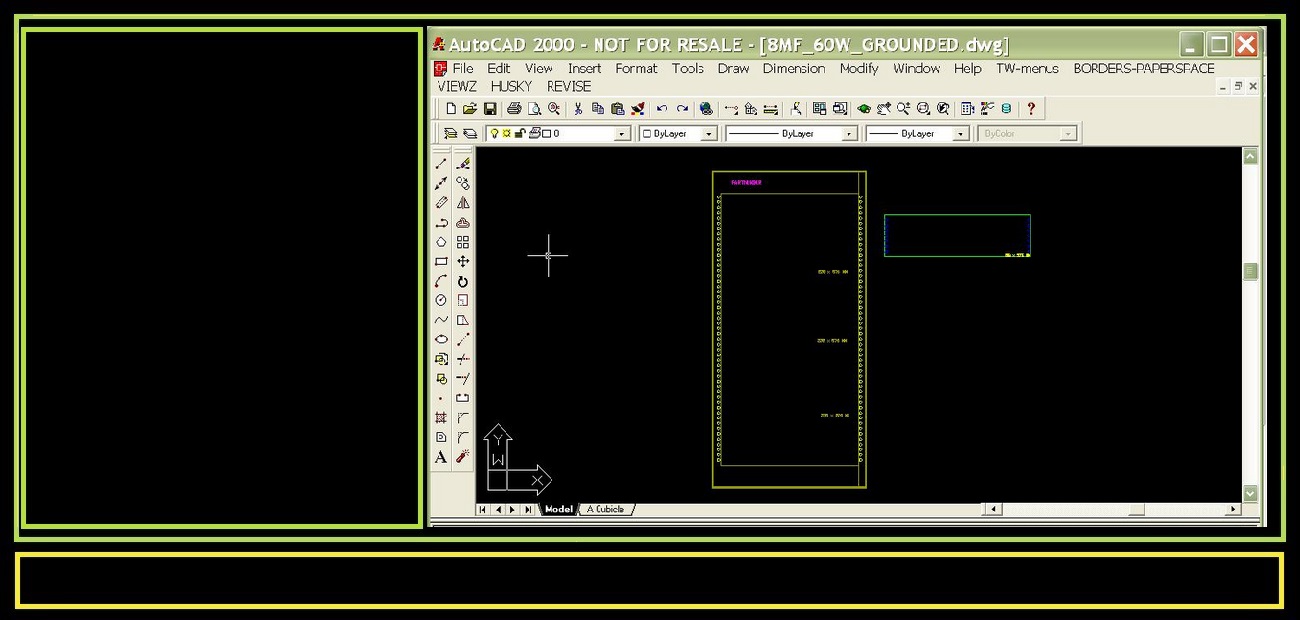

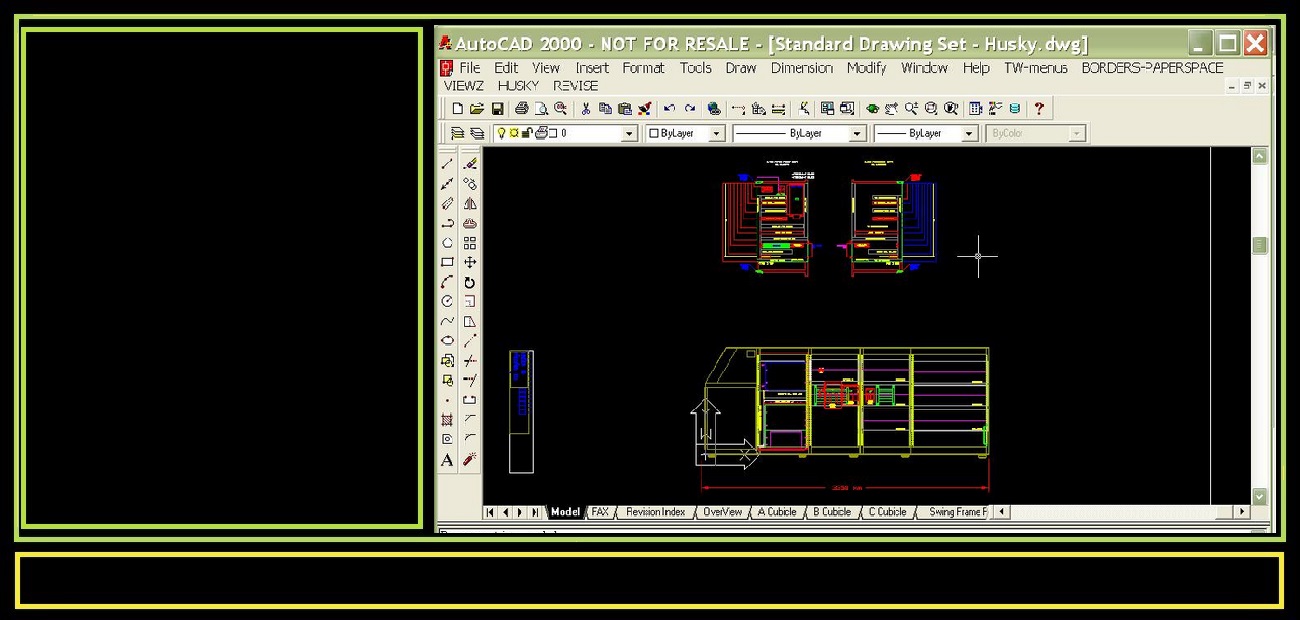

I FLIPPED THE LAYOUTS IN ORDER TO SHOW HIM THE "PRELIMINARY DRAWING" SENT TO THE CUSTOMER FOR APPROVAL. THEN I FLIPPED OTHER LAYOUTS, SHOWING EACH PANEL ASSEMBLY AND THE FINAL COMPLETED DRAWING WHICH WERE BROKEN INTO VARIOUS DESIGN DOCUMENTS FOR EACH WORK CENTER.

.

HE LEFT MY AREA...

I WAS FINALLY OFFERED A JOB IN THE COMPANY I HAD SEARCHED FOR SINCE GRADUATION. (I HAD SPENT 6 YEARS "UNDER-EMPLOYED"). THIS DID NOT SILENCE FUTURE COMPLAINTS AND PROFANITY.(LATER I WAS NOT THE ONLY "TARGET").(THAT PERSON HAD DUAL DEGREES FROM GA TECH ME/EE.)HE IS NOW SR. MANAGEMNT IN "IT", ELSEWHERE(WE ARE LINKEDIN). I'M SURE HE'D CONFIRM MY OBSERVATIONS.(I IGNORED IT BEST I COULD FOR YEARS.)

I WAS NOT APPOINTED AN "ENGINEER" IN THE CAPACITY COMMENSURATE WITH MY DEGREE. BUT THIS DID GIVE ME "AN ENTRANCE", "HOPEFULLY" TO BE ABLE TO DEMONSTRATE MY CAPABILITIES FOR ADVANCEMENT.

MINE SAID

" IT'S NOT TOO LATE TO TURN BACK".

(OTHERS "SNICKERED") (OMINOUS TIDINGS)

TO THIS DAY DESPITE EATING ASIAN CUISINE, NEARLY TWICE WEEKLY,

I'VE SEEN PLENTY OF DUPLICATE FORTUNES, BUT I'VE NEVER SEEN A SIMILAR FORTUNE.(I.J.S.)(LOL)

I WAS ASKED TO SIMILARLY AUTOMATE AND STREAMLINE THE USE OF ALL SOFTWARE TO TRAIN OTHER "NEW HIRES".

I COULD NOW, DESIGN AND DO ALL PROJECT ACTIVITIES "BY MYSELF".

I WORKED WITH THE MANUFACTURING ENGINEER ON "INCREASED EFFICIENCY AND REDUCTION OF REPEATED ERRORS" (DESIGN AND PROCESS IMPROVEMENT).

ON THE RIGHT ARE SEPARATE SELECTION DESIGN MENUS FOR THE "HUSKY"(HIGHLIGHTED) AND "TOKYO ELECTRON" PROJECTS.

1ST - YOU COULD SELECT THE TYPE OF DRAWING TO CREATE. APPROPRIATELY PICKING "BORDER TYPE" AND SET UP OF "TEXT ANNOTATION".

THE MENU ALLOWED THE USER TO FILL IN THE TEXT ATTRIBUTES WITH A SINGLE CLICK THAN TO AIM FOR VARIOUS ATTRIBUTES.

ALSO ALL STANDARD NOTES AND TEXT INPUTS WERE ALREADY THERE FOR INSERTION INTO A "STANDARD SPOT AND LAYER". "SAVING TIME" ON DRAWING SETUP. CREATING "UNIFORM" LOOKING DOCUMENTATION, NO MATTER WHO WOULD DO THE EDITING & DESIGN.

YOU COULD SELECT THE TYPE OF DRAWING SETUP (LAYOUT- ASBUILT) FOR ANY PROJECT I HAD SIMPLIFIED THE DESIGN.

ALL WERE PLACED ON THE SPECIFIC LAYERS AT A "1 TO 1" SCALE.

VARIOUS STANDARD VIEWS WERE ADDED TO SPEED DESIGN.

ALSO AN EXTRA MENU TO HANDLE DESIGN OF VDE MACHINES WITH DIFFERENT CLASS COMPONENTS FOR USE IN EUROPE.

UNTIL I LATER STREAMLINED THIS AS WELL, THERE WERE MANY CONTINUAL ERRORS IN THE "PARTS ORDERING PROCESS" ACCURACY.

WHILE I ALSO DESIGNED ANY NEW MECHANICAL "STRUCTURAL MEMBERS" AND ADDED THEM TO THE MENU SYSTEM, "AS NEEDED".

MORE COULD HAVE BEEN DONE. BUT DESPITE A WIN. THE MANAGER "ASSUMED" THAT AUTOCAD WAS THE "LIMIT OF MY CAPABILITES".

SEEING THE SIMPLICITY OF USING THE MENUS. I WAS TOLD TO TRAIN OTHERS TO DESIGN THE PROJECTS, USING MY TOOLS AND DESIGNS.

ONCE I READ THE BOOK ON THE "REAL USE" OF THE SOFTWARE: EPLAN, AND PROMIS-E. I GOT TO WORK, TO SELF LEARN AND AUTOMATE THE EXTRACTION OF WIRE DATA FROM DRAWINGS USING THESE SOFTWARE. I NOTICED WE HAD HIRED SOMEONE FROM ASSEMBLY TO CREATE "WIRE LISTS". HE WAS STRUGGLING AND EVERYONE WAS IRRITAED AT THE ERRORS. BUT HE WAS POISED TO BE PROMOTED. HE QUIT OUR COMPANY AND FOUND A FULL ENGINEERING JOB WITH "GE" DESPITE HAVING NO EXPERIENCE OR DEGREE. BECAUSE HE NETWORKED CONNECTIONS.

DESPITE TRAINING OTHERS,I COULD NOW DO EVERY ASPECT OF THE PROJECTS FROM DESIGN TO PROJECT MANAGEMENT WITH "NO ASSISTANCE", BETTER AND FASTER THAN ANYONE. ALL THE TOOLS WERE MY DESIGN. I COULD EVEN MAINTAIN MULTI-UNIT PRODUCTION LEVELS BY MYSELF IF REQUIRED. THE CUSTOMER HAD COMPLETE CONFIDENCE IN MY DESIGN AND TEND TO CONTACT ME FOR PRODUCT ASSISTANCE AND IMPROVEMENT. BUT NO ONE MENTIONED PROMOTION OR CHANCES TO ME. THEY HIRED EXTERNALLY AND ASKED ME TO TRAIN. ONE HAD A DEGREE IN "PHYSICAL EDUCATION". I WAS DISSUADED FROM APLYING- BY THE DETRACTOR AND OUR NEW MANAGER (NOW FRIENDS).

I THEN DID ECO'S, ECNS AND PERFORMED PRODUCT IMPROVEMENT AND ERROR REDUCTION WITH THE SYSTEMS' ENGINEER. (ALSO UNDEGREED)- NO LONGER IN ENGINEERING.

WHEN THEY MADE AN SIGNIFICANT ERROR- I WAS CALLED FROM MY NEW JOB AND ADRESSED IN FRONT OF THE CUSTOMER AS IF I HAD MADE THE ERRORS FOR THEIR DEPARTMENT TO SAVE FACE. MY MANAGER TOLD ME TO STOP SUPPORTING THEIR DEPARTMENT. I GUESS IT WAS ANTICIPATED THEY COULD DUPLICATE MY SKILLS AS I LEFT THE DEPARTMENT. ("INEXPERIENCED", THEY HAD "JUST TAKEN" AN AUTOCAD COURSE). MENU PROGRAMMING IS NOT TAUGHT IN A "LEVEL 1" AUTOCAD CLASS. AND I HAD BEEN "SELF-TAUGHT", SINCE NO SCHOOL, I KNEW OF, TAUGHT A CLASS IN CUSTOMIZATION.

mY FORMER DETRACTOR TAUNTED ME TO SAY THEY HAD BOUGHT AN AUTOCAD BOOK AND WOULD SOON BE ABLE TO DO WHATEVER I DEVELOPED. THEY SAT WITH THE BOOK DAILY TRYING TO LEARN AUTOLISP AND MENUS. I HAD BEEN HIRED IN ANOTHER DEPARTMENT AS AN ENGINEER. AUTOCAD "CHANGED" MAKING THE "MENU SYSTEM I CREATED FOR THEM OBSOLETE" AND REQUIRING RECODING. (MNX CHANGED TO CUIX.

THEY SPENT MONTHS WITH THE ENGINEER AND THE "AUTOCAD BIBLE"- TRYING DUPLICATE MY DEVELOPMENT. 2 YEARS LATER THEY STILL HAD NOT ACCOMPLISHED THIS.

SO IT APPEARS MY DEVELOPMENT "WAS" "HIGHLY USEFUL", "PRODUCTIVE" AND "SIGNIFICANT" ENOUGH TO TRY AND EMULATE.

I WAS INFORMED SOME KEPT THEIR DEVELOPMENT SECRETS TO PICK THEIR REPLACEMENTS WHEN THEY LEFT. SO PEOPLE WERE POSESSIVE OF "PLC AND HMI" DEVELOPMENT, FURTHER LIMITING MY CHANCES AT ADVANCEMENT, WHICH HELPED STALL MY CAREER. I WOULD BE "STELLAR" BY NOW IF I ONLY HAD ANY MENTORING TO GET ME STARTED, LIKE OTHERS AROUND ME.