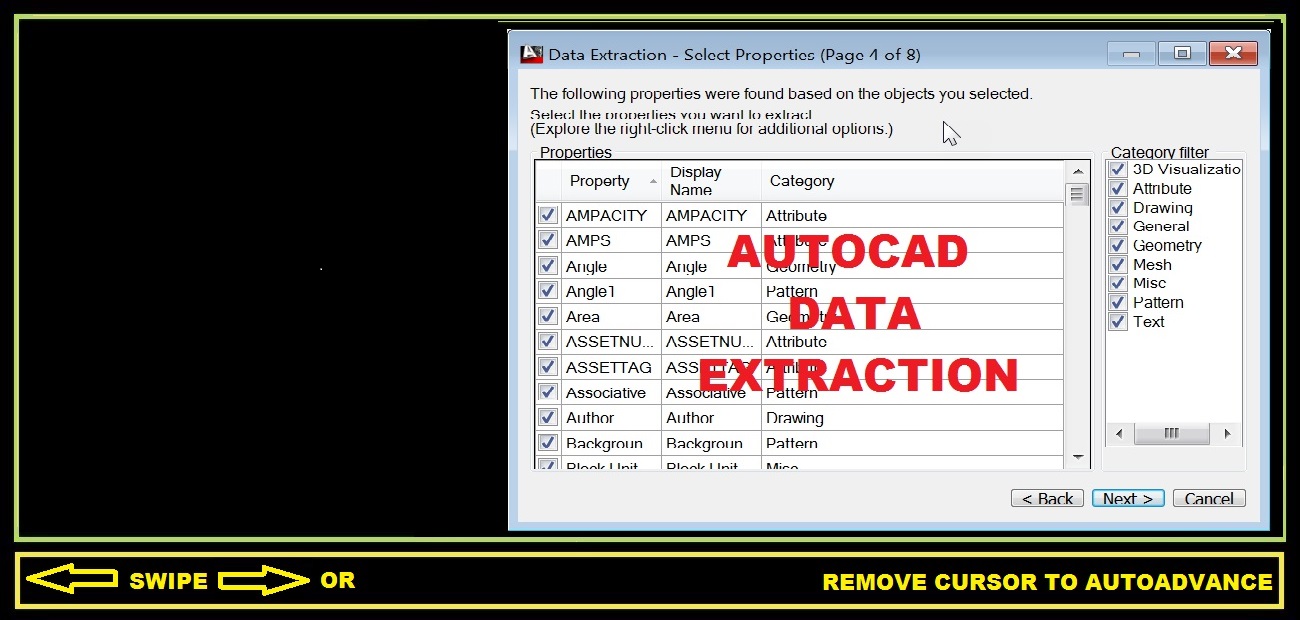

AUTOCAD DATA EXTRACTION

SYSTEMS

ASSET MANAGEMENT

DOCUMENTS/ ASSETS

SERVICE: ASSET TRACKING-DATABASE MGMT.

CUSTOMERS: SIEMENS- WRIGLEY

DATE: 1993-2018

ASSET TRACKING

THEORY: "BIM"-"PIM"

THIS "DEMO" INVOLVES DATA ENCAPSULATION AND EXTRACTION FROM DRAWINGS.

IT HAS BEEN AS EQUALLY USEFUL IN "MANUFACTURING" AS IT IS IN "CONSTRUCTION".

THERE ARE PROGRAMS LIKE "REVIT" WHICH ARE DESIGNED FOR MANAGING EQUIPMENT AND PART INFORMATION. I HAVE BEEN DOING THIS SINCE 1991 IN AUTOCAD. I WAS A FEW YEARS AHEAD OF AUTODESK BY TRYING TO DEVELOP: MENU, AUTOLISP AND ATTRIBUTE EXTRACTION W/ 3D MODELING INTO A BUILDING /MANUAFCTURING TOOL.

IT WAS A USEFUL TOOL FOR "TRACKING ASSETS", "BILLS OF MATERIALS" AND "ESTIMATING COSTS".

IT HAS BEEN AS EQUALLY USEFUL IN "MANUFACTURING" AS IT IS IN "CONSTRUCTION".

THERE ARE PROGRAMS LIKE "REVIT" WHICH ARE DESIGNED FOR MANAGING EQUIPMENT AND PART INFORMATION. I HAVE BEEN DOING THIS SINCE 1991 IN AUTOCAD. I WAS A FEW YEARS AHEAD OF AUTODESK BY TRYING TO DEVELOP: MENU, AUTOLISP AND ATTRIBUTE EXTRACTION W/ 3D MODELING INTO A BUILDING /MANUAFCTURING TOOL.

IT WAS A USEFUL TOOL FOR "TRACKING ASSETS", "BILLS OF MATERIALS" AND "ESTIMATING COSTS".

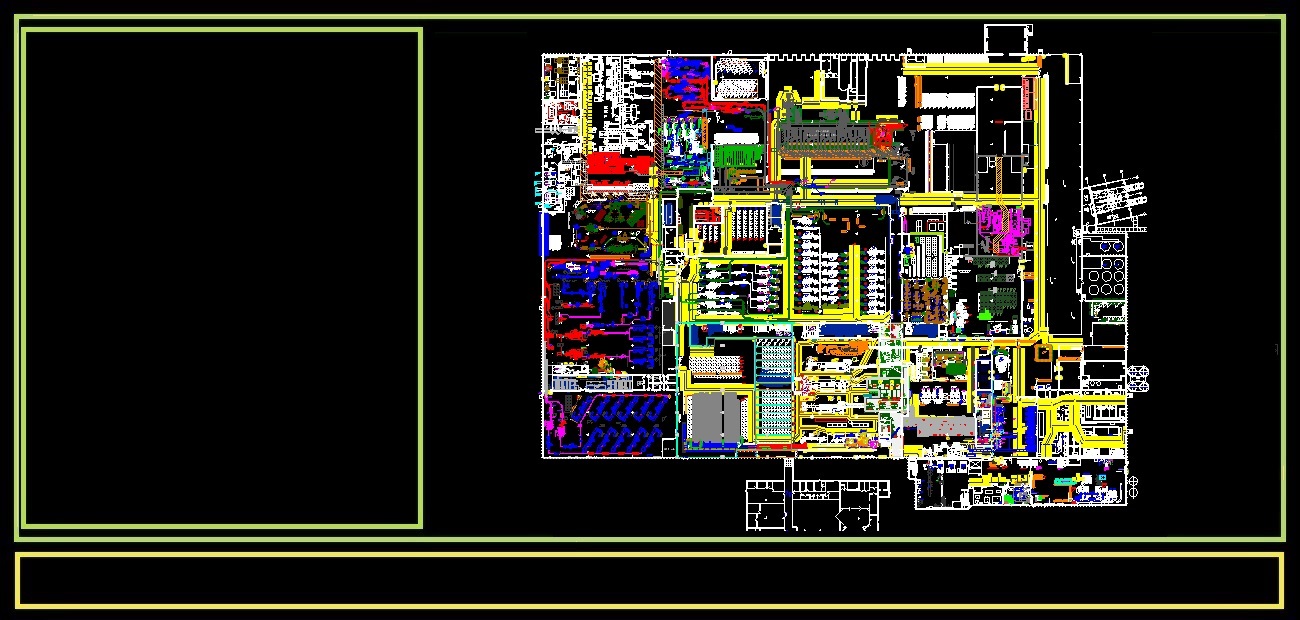

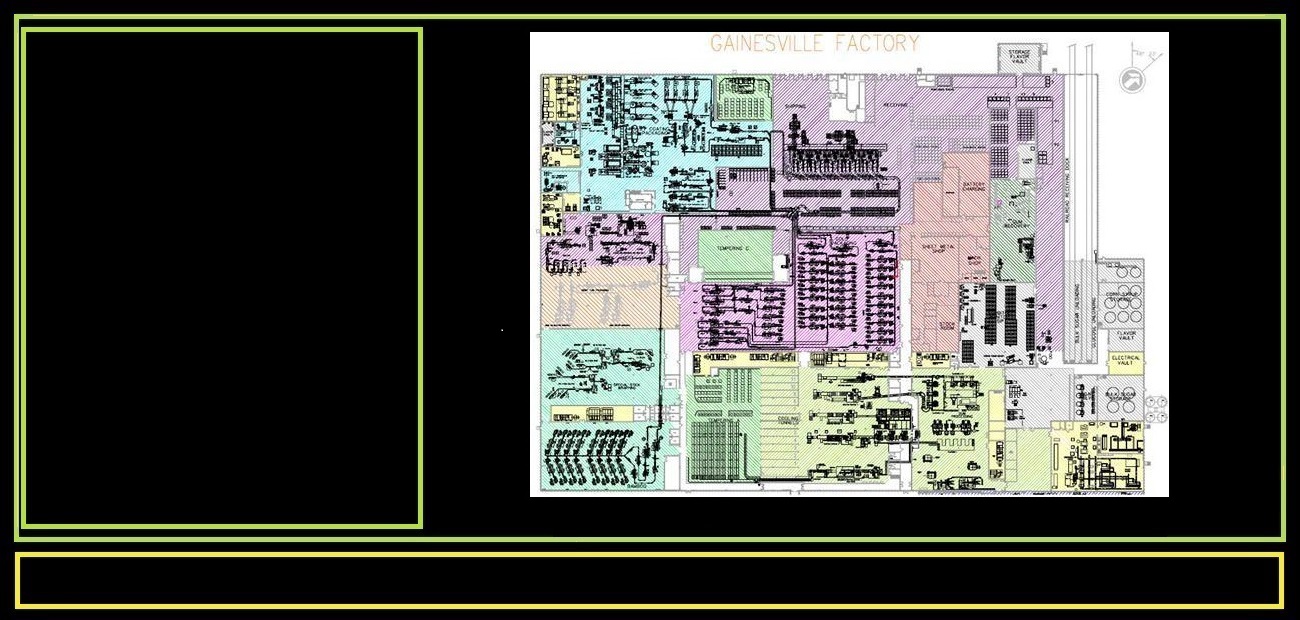

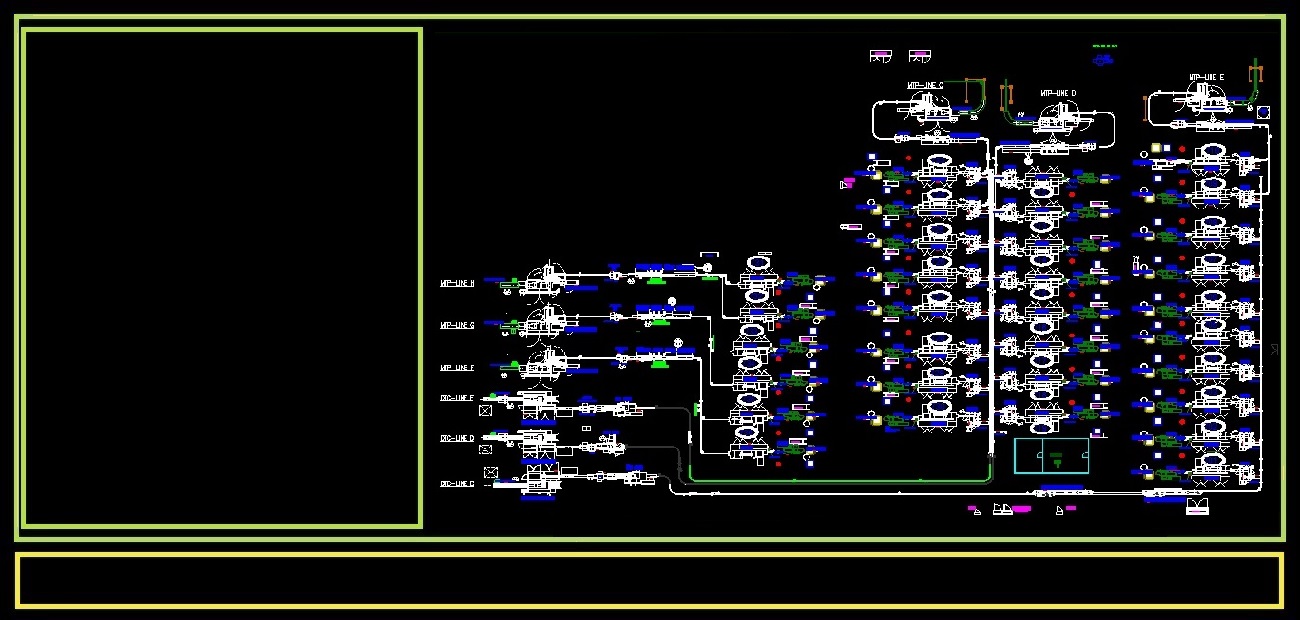

"ON YOUR RIGHT" IS A FACILITY LAYOUT I CREATED. THIS SHOWS ALL THE EQUIPMENT IN EVERY PART OF THE FACILITY. DRAWINGS THAT PRE-EXISTED MY EMPLOYMENT WERE SPORADIC AND INCOMPLETE. I MADE IT A POINT TO MAKE THE EXACT REPRESENTATION OF ALL EQUIPMENT PLACEMENT OF THE FACILTY IN CAD FOR "AN ACCURATE DESIGN TOOL" AND "ASSET TRACKING."

DRAWING DATA

AUTOCAD AND MICROSTATION

I WAS RESPONSIBLE FOR MAINTAINING A DRAWING OF THE ENTIRE FACILITIES CONTENTS ON AN "UP TO DATE BASIS". MEANING "EVERY DEVICE OR PIECE OF EQUIPMENT" IS SHOWN AS IT SITS PRESENTLY IN THE FACILITY. THE DRAWING IS CONSISTANTLY MODIFIED AS EQUIPMENT IS INSTALLED, RELOCATED OR REMOVED. I PHYSICALLY MATCHED THE DIMENSIONS IN REAL PLACEMENT. FROM THE DRAWING, YOU CAN MEASURE THE EXACT PLACEMENT OF EACH PIECE OF EQUIPMENT AND IT WILL MATCH THE EXACT PLACEMENT ON THE FACTORY FLOOR IF YOU WERE TO MAKE A MEASUREMENT OF EITHER FORMAT.

HERE IS THE COMPLETE FACILITY LAYOUT, SHOWING ALL THE EQUIPMENT. THE AREAS ARE SHADED BY FUNCTION SO INFORMATION CAN BE IDENTIFIED BY THEIR PARTICULAR COST CENTER.

DATA ENCAPSULATION

AUTOCAD AND MICROSTATION

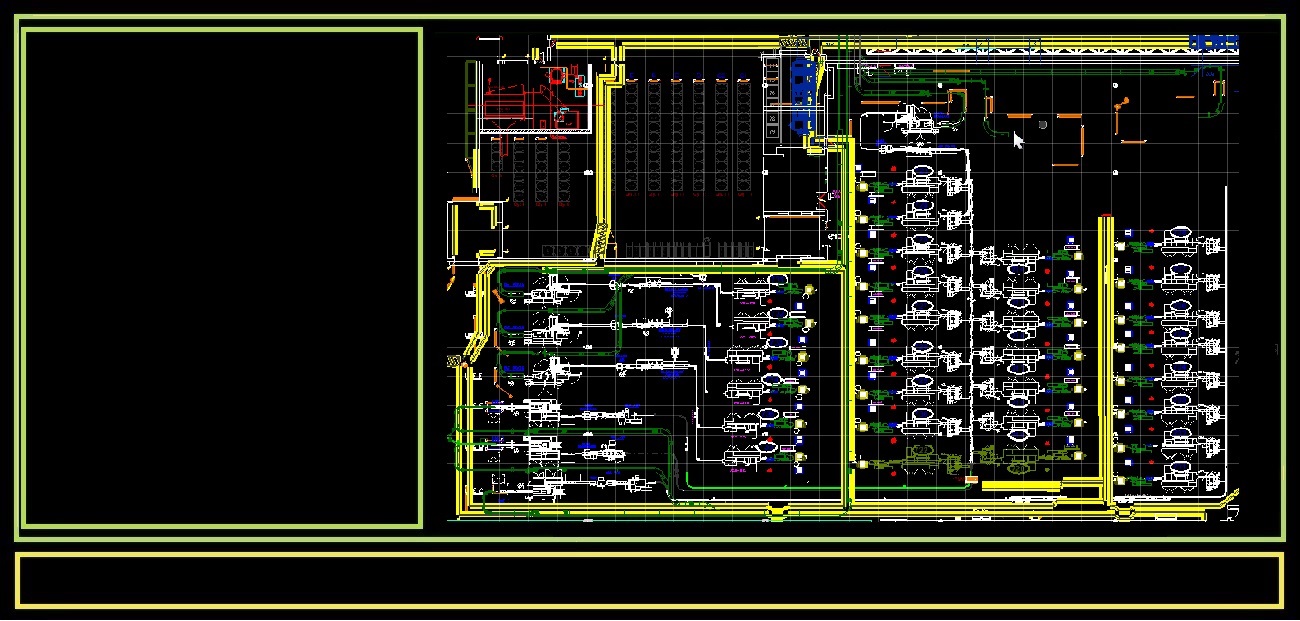

TO SIMPLIFY DESIGN AND DRAWING MODIFICATION, EACH AREA OF THE FACTORY IS BROKEN INTO A SEPARATE DRAWINGS, SIMPLIFYING "SELECTIVE" DATA EXTRACTION. THE IDEA WAS BEING ABLE TO MAKE UPDATES AND EXTRACT DATA EITHER GLOBALLY OR FOR A SINGLE DEPARTMENT. I ENHANCED TIME EFFICIENCY, NOT HAVING TO OPEN A LARGE DRAWING. AND EASE OF UPDATE OF INDIVIUAL ROOMS AND PRODUCTION AREAS. ENHANCING THE ABILITY TO BE ABLE TO PRODUCE SINGLE SMALLER DRAWINGS OR PDFS UPON REQUEST OR TO BE ABLE TO WORK ON A SINGLE FACTORY SECTION, FOR CONSTRUCTION OR DESIGN PURPOSES, RATHER THAN TO SEND THE ENTIRE FACILITY DRAWING OUT TO CONTRACT CONSULTANTS. (SECURITY OF COMPANY INFORMATION)

HERE IS THE LAYOUT OUT OF ONE SINGULAR AREA AND THE EQUIPMENT CONTAINED WITHIN. MEASUREMENTS CAN BE TAKEN FROM THE EXISTING DRAWING TO DETERMINE EQUIPMENT PLACEMENT AND SPACING FOR DESIGN PURPOSES. THIS REQUIRED ME TO "HAND MEASURE" "EACH AND EVERY PIECE" OF EQUIPMENT IN THE FACILITY. I MEASURED EQUIPMENT LOCATION RELATIVE TO FIXED POINTS ON THE FACTORY FLOOR PLAN AND CREATED THE MATCHING DRAWINGS.

HERE IS THE SAME LAYOUT. HERE I REMOVED THE BACKGROUND FLOOR PLAN TO CONCENTRATE ONLY ON THE EQUIPMENT. I AM A FORCE OF "ONE", ADDITIONAL "HELP" ONLY TENDS TO MAKE THE JOB TEDIOUS. "ONE MIND" CREATES CONSISTENCY AND STANDARDIZATION.

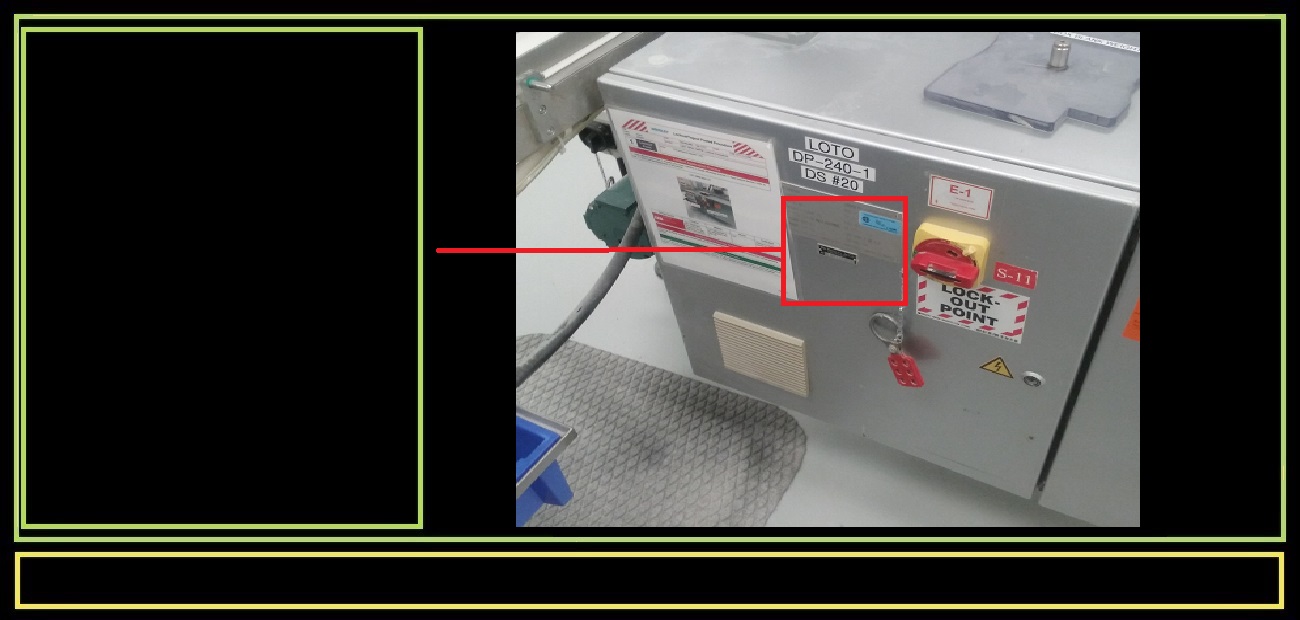

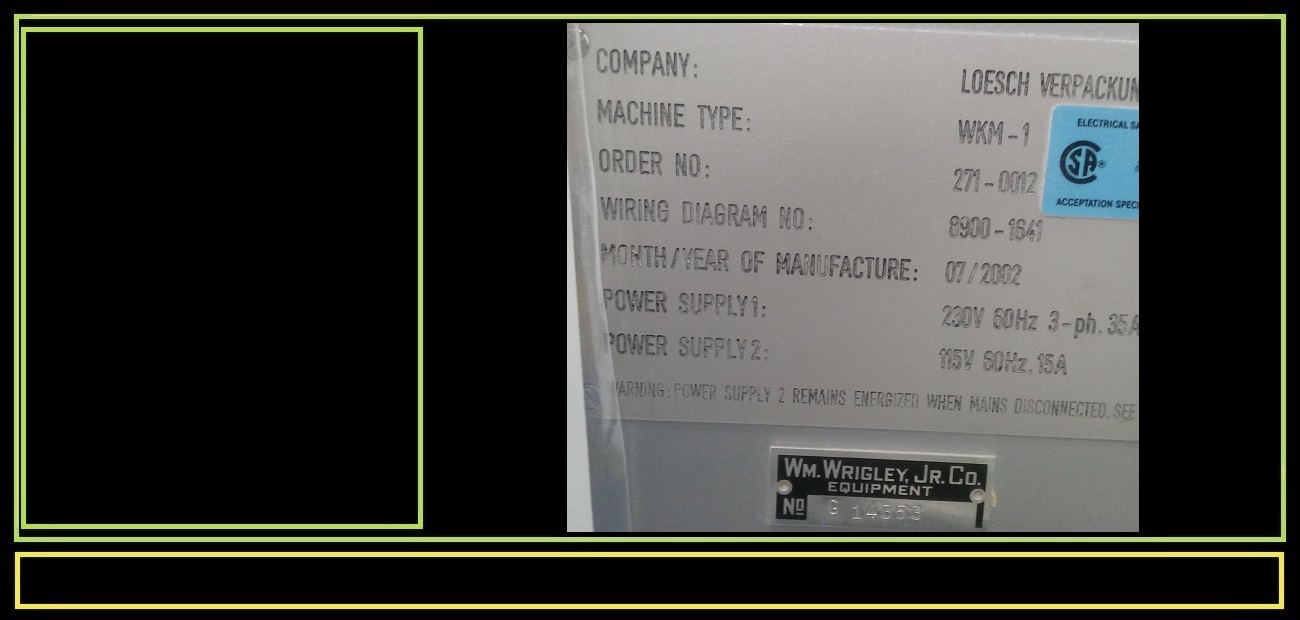

MY RESPONSIBILITY INCLUDED THE TRACKING OF ALL "CAPITAL ASSETS". MOST EQUIPMENT HAD ASSET TAGS TO IDENTIFY IT AGAINST THE MASTER DATABASE FOR ACCOUNTING PURPOSES. EACH ITEM HAD RATING PLATES WHICH IDENTIFIED THE PROPERTIES OF THE EQUIPMENT. I DECIDED TO IDENTIFY AND RETRIEVE EVERY BIT OF IDENTIFIABLE INFORMATION ON EACH MACHINE. THIS TASK WAS DONE OFTEN DURING OPERATION AND PRODUCTION - THIS REQUIRED ME TO WORK IN AND AROUND HIGH SPEED EQUIPMENT AND CONVEYORS, TO "FIND THE INFORMATION". OVER TIME, I HAVE MADE CONTACT WITH EVERY INDIVIDUAL ITEM IN THE FACILITY.

HERE IS A CLOSE UP OF AN ASSET TAG LOCATION. FOR YEARS, I ASSIGNED A TAG TO EACH PIECE OF EQUIPMENT DURING "CAPITALIZATION". I ALSO FOUND AND CAPTURED DATA FROM THE RATING PLATE OF A EACH MACHINE. SOMETIMES THIS INFORMATION VIEWING WAS "INCONVENIENT". PLATES WERE INSTALLED IN PLACES, THAT I OFTEN HAD TO LAY ON THE FLOOR OR STAND OVER "ACTIVE PRODUCTION" MACHINES TO VIEW AND DOCUMENT INFORMATION FOR MY DATA BASE.

DATA ENCAPSULATION

Position: DATA ENCAPSULATION

TRACKING EQUIPMENT WAS DIFFICULT, BECAUSE I WAS NOT TYPICALLY INFORMED OF REPLACEMENT, MOVING OR RETIRING OF EQUIPMENT. I CONDUCTED REGULAR INSPECTIONS TO DETERMINE IF EQUIPMENT CHANGES WERE MADE.

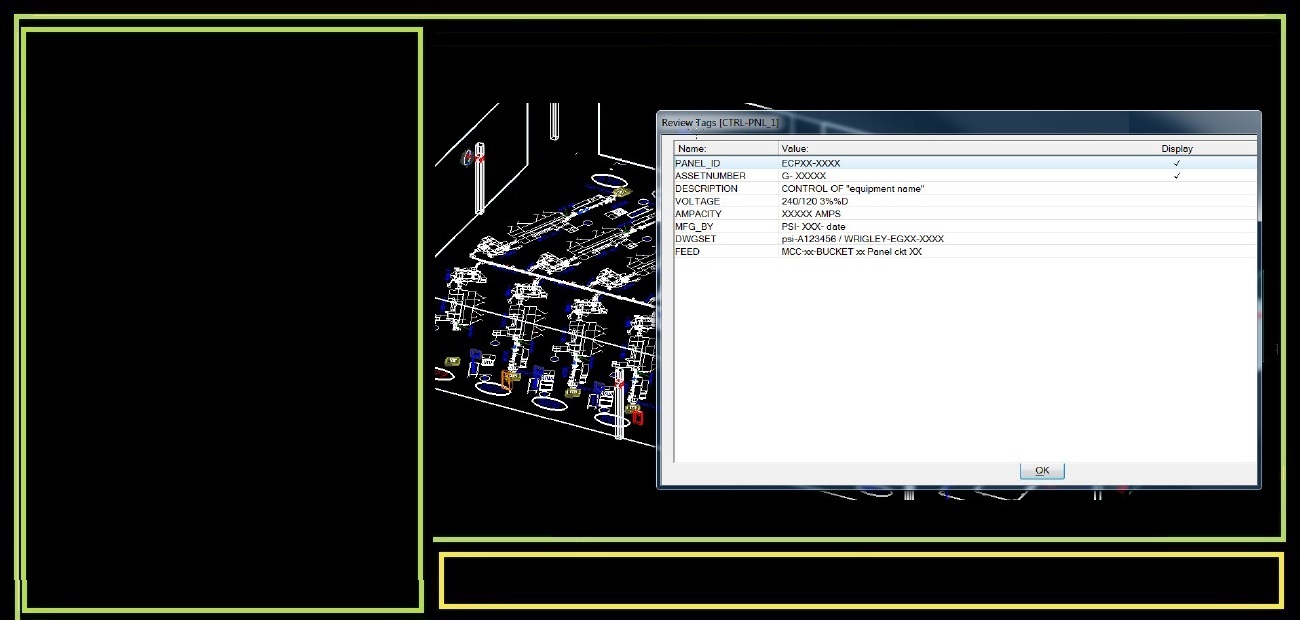

I AM PRESENTLY ENCAPSULATING THE DATA INTO THE DRAWING ITSELF SO THAT EACH ASSET COULD BE TRACKED AND IDENTIFIED, WITH ALL OF ITS MANUFACTURED PROPERTIES AND RATINGS, IN THE DRAWING, WITHOUT A VISIT TO THE FACTORY FLOOR TO IDENTIFY INFORMATION.

I AM PRESENTLY ENCAPSULATING THE DATA INTO THE DRAWING ITSELF SO THAT EACH ASSET COULD BE TRACKED AND IDENTIFIED, WITH ALL OF ITS MANUFACTURED PROPERTIES AND RATINGS, IN THE DRAWING, WITHOUT A VISIT TO THE FACTORY FLOOR TO IDENTIFY INFORMATION.

BOTH MICROSTATION AND AUTOCAD RECOGNIZES AND USES ATTRIBUTE ENCAPSULATION. SO I THEN DESIGNED EACH DRAWING SYMBOL AS A DATA CONTAINER THAT HELD THE IDENTIFYING PROPERTY OF THE EQUIPMENT.

SELECTING THE EQUIPMENT BY MOUSE CLICK, PRODUCED A "POP UP" DIALOG WHICH DISPLAYED THE PROPERTIES OF THE EQUIPMENT. THIS ALLOWED ONE TO SEE DATA WITHOUT HAVING TO PHYSICALLY GO LOOK AT THE MACHINE. I RECOGNIZED MICROSTATION HAD A VIEWER, WHICH WOULD ALLOW ANYONE IN THE FACTORY WITH ACCESS TO INFORMATION. FOR FREE. HAD THEY BEEN AWARE OF THIS IT WOULD HAVE UNIFIED PLANT OPERATIONS FOR MAINTENANCE, ENGINEERING AND ACCOUNTING WELL. THIS IS THE PROBLEM, IN NOT KNOWING THE CAPABILTIES OF CAD AND THE TOOLS YOU ALREADY HAVE. NOW MICROSTATION IS BEING DEPRICATED. SO I CEASED DEVELOPMENT. NO ONE BEFORE ME CONSIDERED THE POSSIBILITIES TO IMPROVE PROCESSES.

SELECTING THE EQUIPMENT BY MOUSE CLICK, PRODUCED A "POP UP" DIALOG WHICH DISPLAYED THE PROPERTIES OF THE EQUIPMENT. THIS ALLOWED ONE TO SEE DATA WITHOUT HAVING TO PHYSICALLY GO LOOK AT THE MACHINE. I RECOGNIZED MICROSTATION HAD A VIEWER, WHICH WOULD ALLOW ANYONE IN THE FACTORY WITH ACCESS TO INFORMATION. FOR FREE. HAD THEY BEEN AWARE OF THIS IT WOULD HAVE UNIFIED PLANT OPERATIONS FOR MAINTENANCE, ENGINEERING AND ACCOUNTING WELL. THIS IS THE PROBLEM, IN NOT KNOWING THE CAPABILTIES OF CAD AND THE TOOLS YOU ALREADY HAVE. NOW MICROSTATION IS BEING DEPRICATED. SO I CEASED DEVELOPMENT. NO ONE BEFORE ME CONSIDERED THE POSSIBILITIES TO IMPROVE PROCESSES.

DATA EXTRACTION

EQUIPMENT IDENTIFICATION

THIS CAME IN HANDY FOR TRACKING. WHEN MOVING EQUIPMENT I COULD SIMPLY MOVE THE CORRESPONDING IMAGE IN THE DRAWING TO ITS NEW LOCATION. WHEN DEPRECATING OLD EQUIPMENT, I COULD CREATE A GROUP AND EXTRACT THE INFORMATION FROM THE DEVICES REMOVED IMAGES AND RELATE ALL THE INFORMATION TO THE ENGINEER FOR "FILLING OUT ASSET REMOVAL FORMS" OR TO ACCOUNTING TO CHANGE THE MASTER ASSET LIST. ACCOUNTING COULD THEN IDENTIFY EQUIPMENT AND CROSS REFERENCE TO "SAP" TO EVALUATE THE ASSETS VALUE. HAD I CONTINUED DEVELOPMENT, VARIOUS EMPLOYEES COULD THEN NAVIGATE AND LOCATE PARTS AND EQUIPMENT FOR FREE IN BENTLY VIEWER IF THEY HAD NO KNOWLEDGE OF THE PLANT- EXCEPT FOR PART NAME OR ITS PHYSICAL LOCATION. EVEN MAKE MEASUREMENTS FOR DESIGN DIRECTLY FROM ANY COMPUTER.

BUT THEY DECIDED TO DEPRICATE MICROSTATION. I STILL USE THE INFORMATION TO MAINTAIN AN "EXCEL EQUIPMENT LIST".

BUT THEY DECIDED TO DEPRICATE MICROSTATION. I STILL USE THE INFORMATION TO MAINTAIN AN "EXCEL EQUIPMENT LIST".

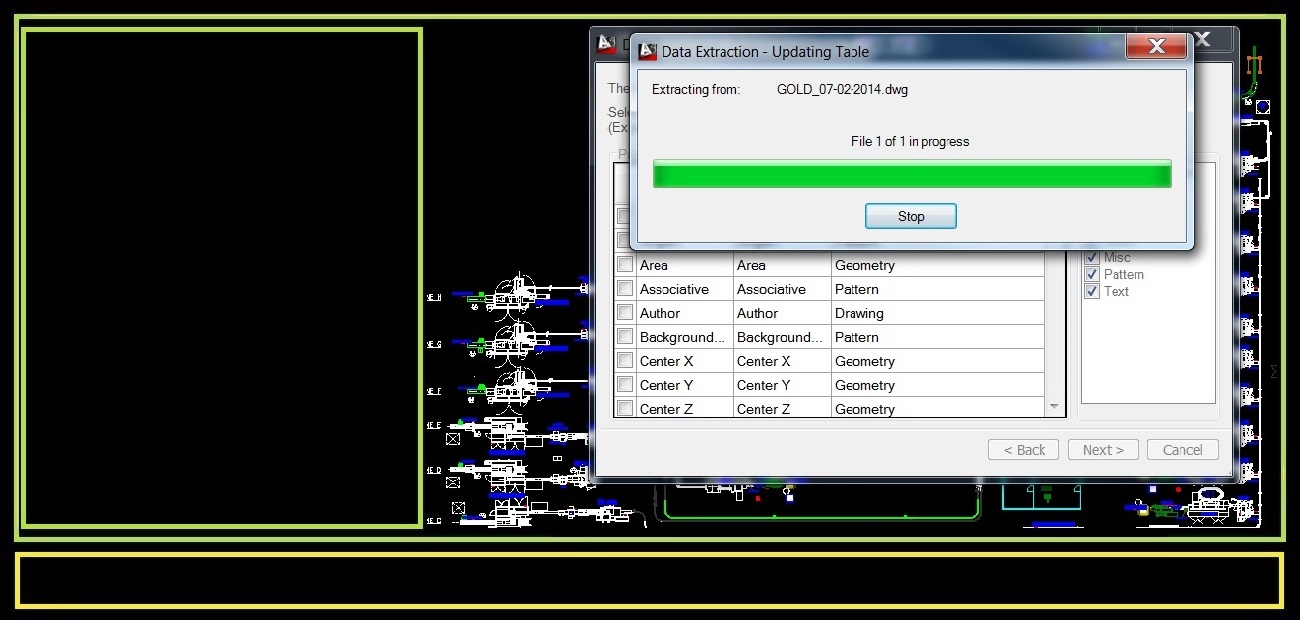

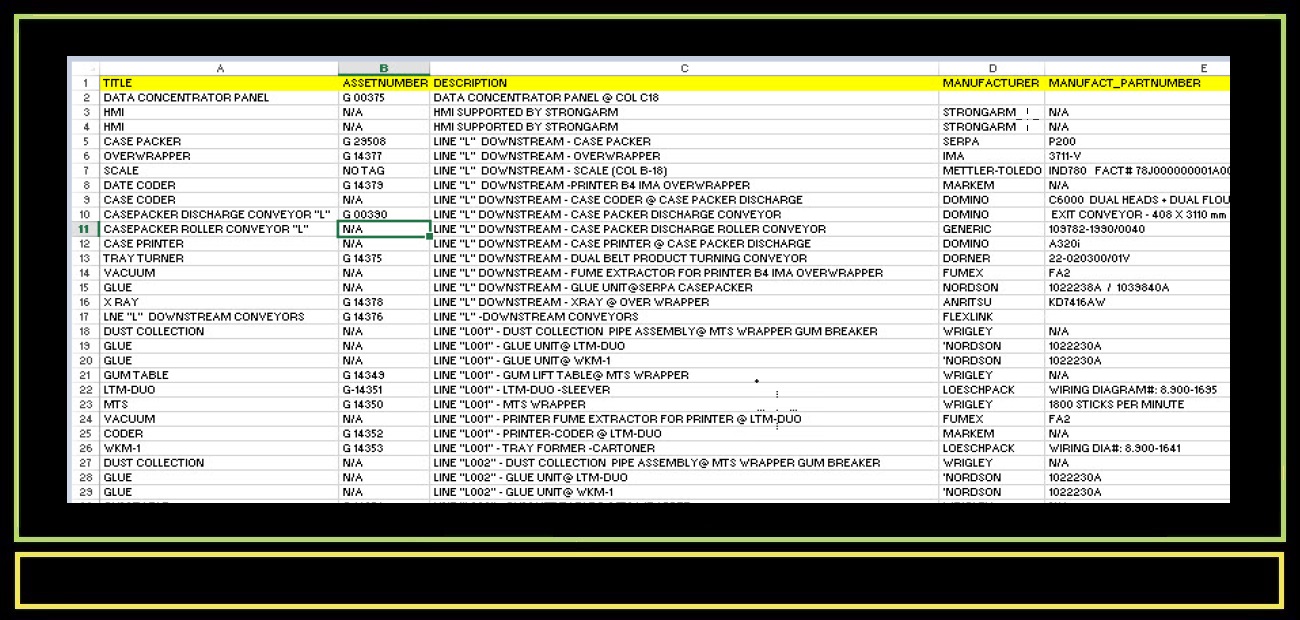

HERE I AM USING AUTOCAD TO EXTRACT THE "DATA EMBEDDED" IN THE BLOCKS "REPRESENTING EACH INDIVIDUAL PIECE OF EQUIPMENT."

AUTOCAD EXPORTS A "UNSORTED LIST" OF THE EQUIPMENT AND ASSOCIATED DATA INTO A FILE. IN THE "OLD DAYS", I HAD TO CREATE A "DATA TEMPLATE" AND AN "ASSOCIATED FORMAT CODE" TO GENERATE A GRID AND EACH TYPE OF DATA TO BE EXTRACTED. I HAD OPTIONS TO EXTRACT SELECTIVE DATA FOR ANALYSIS. I CAN EXTRACT SELECTED DATA FOR DIFFERENT USES AND REPORTS. THIS PROCESS HAS BEEN SIMPLIFIED BY "AUTOLISP PROGRAMMING", AUTODESK HAS PLACED THIS INTO THE AUTOCAD MENU AND DATA EXTRACTION PROCESS, LIKE I USED TO WHEN IT WAS LESS INTUITIVE IN AUTOCAD YEARS AGO.

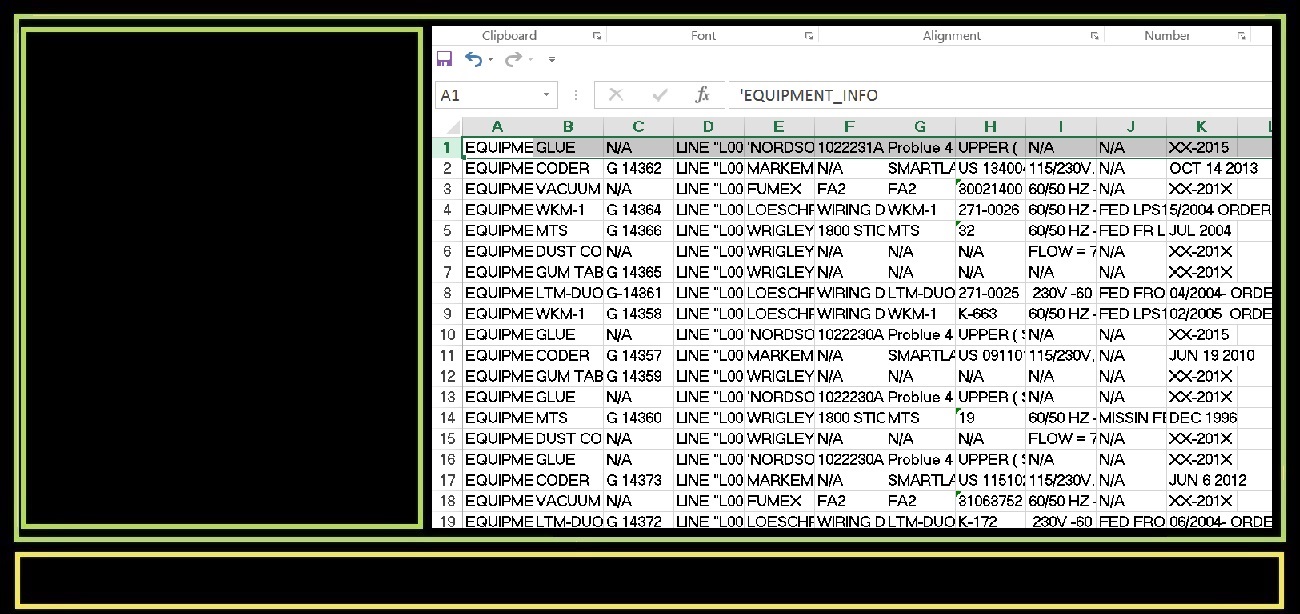

I ADDED HEADERS FOR EACH EXTRACTED VALUE FOR CLARITY.

CONVERT THE DATA

Position: DATA ENCAPSULATION

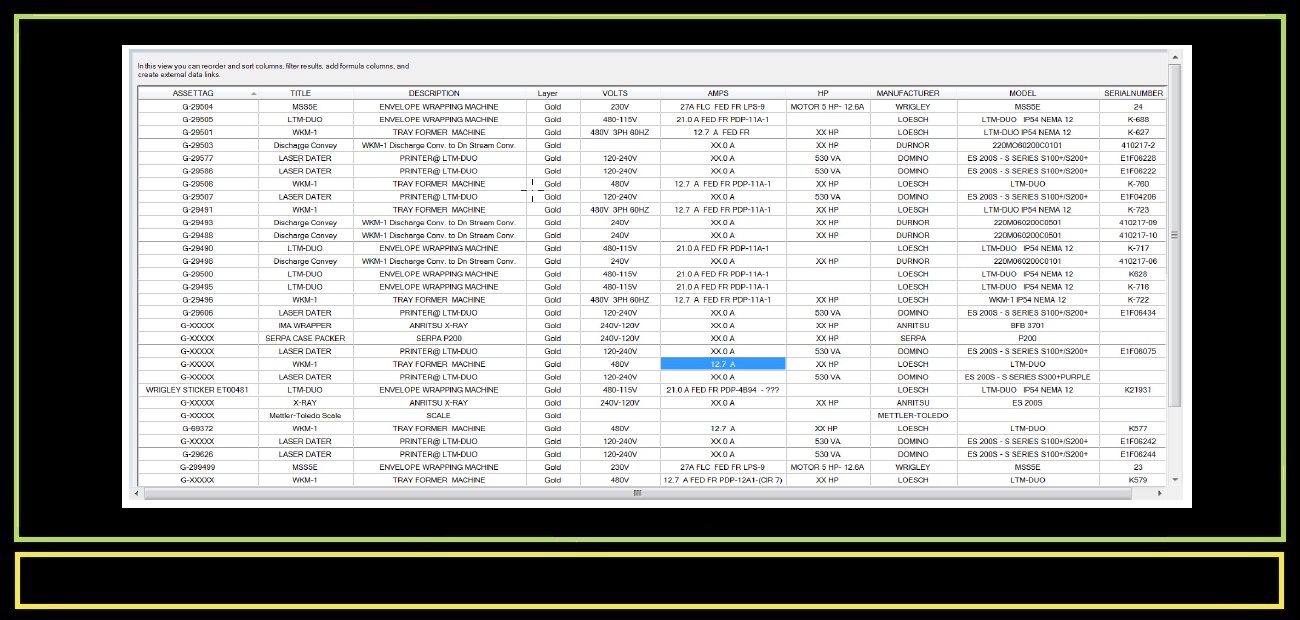

BY CAREFUL STANDARDIZATION. I WAS THEN ABLE TO USE "AUTOCAD OR MICROSTATION" TO EXTRACT DATA AS REQUESTED. I COULD IDENTIFY AN AREA AND EXTRACT A LIST OF ALL EQUIPMENT RELATED TO A CERTAIN FUNCTION OR A CERTAIN COST CENTER. I COULD ALSO DO SEARCHES THAT ALLOWED ME TO FIND A SINGULAR PIECE OF EQUIPMENT AND "ID" ITS PHYSICAL LOCATION IN THE ENTIRE PLANT, WITH COORDINATES TO LOCATE THE EQUIPMENT IN THE MASTER DRAWING.

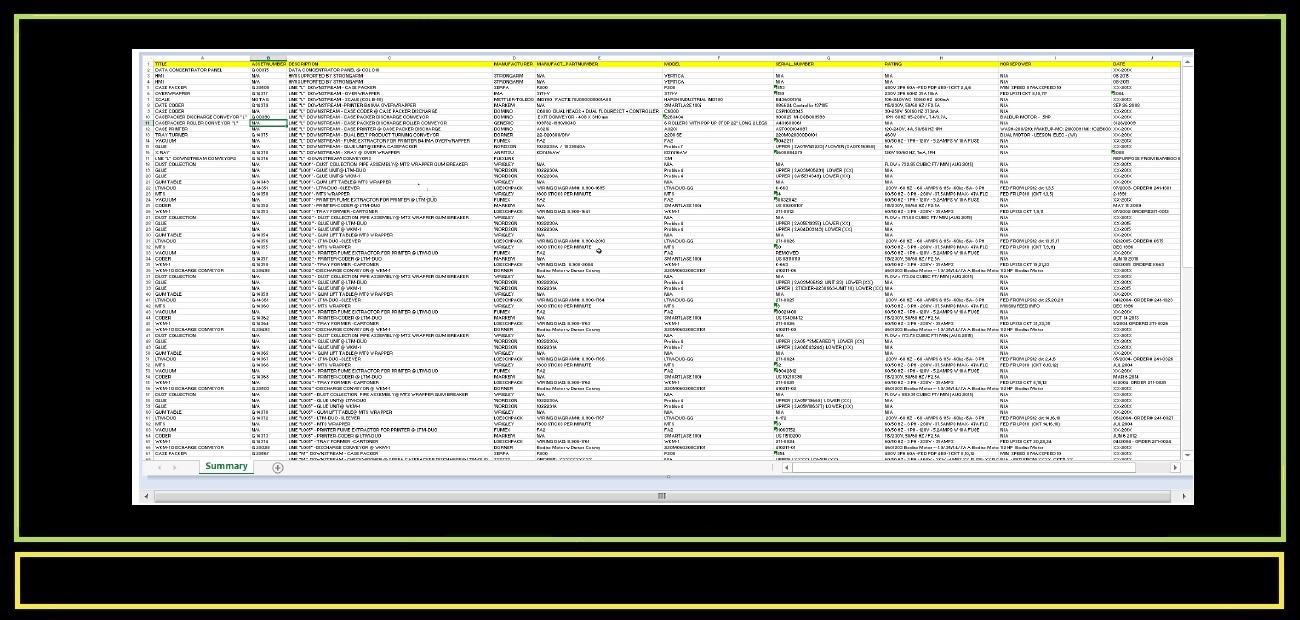

HERE IS THE DATA IN A "SPREADSHEET FORMAT" FOR USE IN EXCEL.

EXCEL SPREADSHEETS ALLOWED SEARCHES AND SORTING. WHILE I WOULD USE MSACCESS TO GENERATE "QUERIES AND REPORTS".

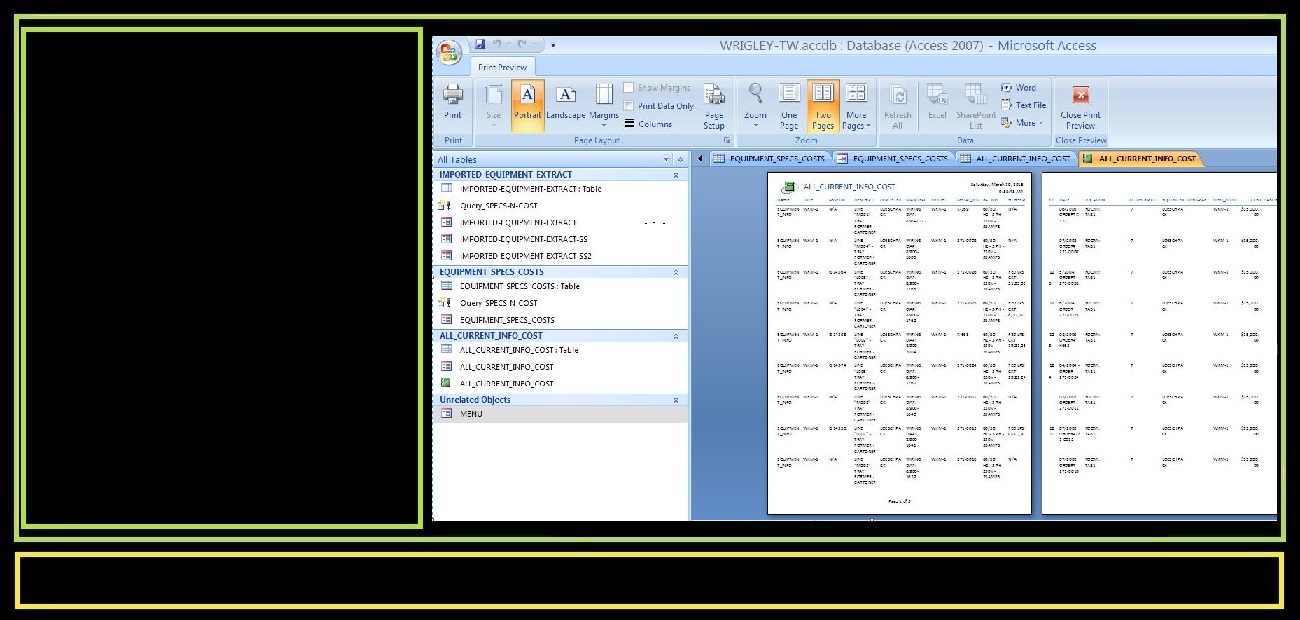

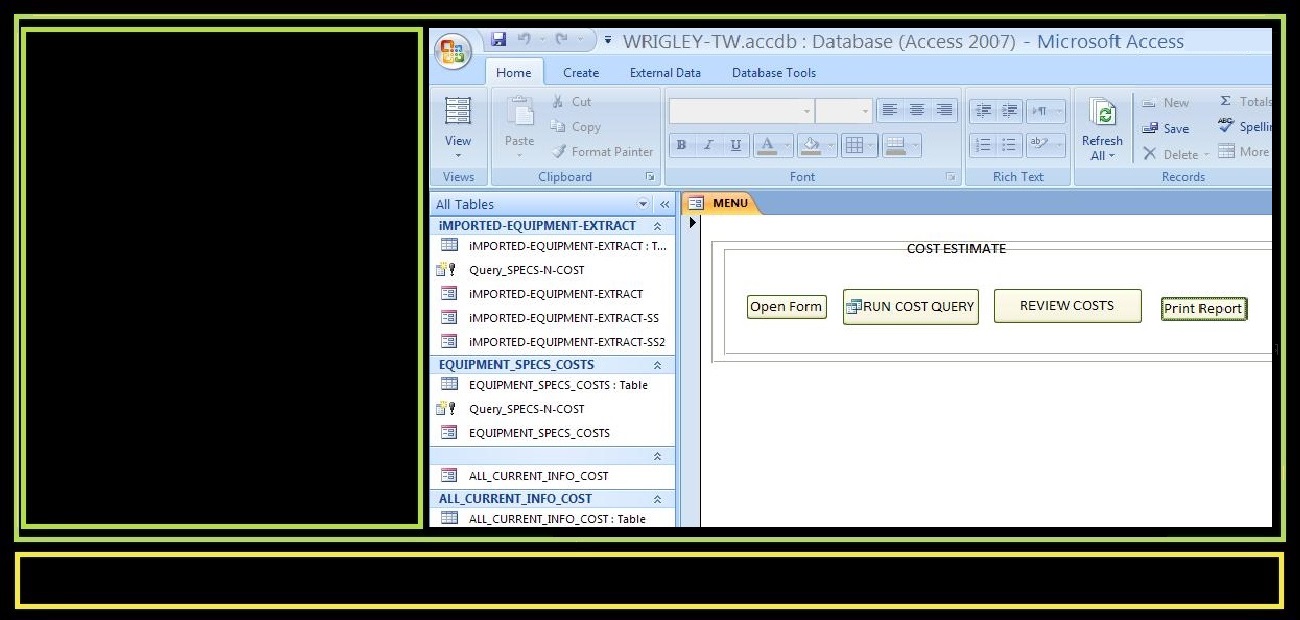

MS ACCESS REPORTS

Position: DATA ENCAPSULATION

I CREATED REPORT TEMPLATES BASED ON QUERIES AND CREATED REPORT TEMPLATES FOR VARIOUS DEPARTMENTS AND REASONS. RETRIEVED DATA COULD BE AUTOMATICALLY FORMATED SAVING TIME. REFERENTIAL INTEGRITY WAS ASSURED WHEN DELETING RECORDS. MY SYSTEM HAD GREATER CONTROL, ACCURACY AND SPEED BEING ABLE TO GET THE MOST UP TO DATE DATA, AS LONG AS, THE DRAWINGS WERE KEPT UP TO DATE.

WHEN USING DATA EXTRACTION IN EQUIPMENT MANUFACTURING, SINCE ALL THE MICROSOFT OFFICE PRODUCTS ARE COMPATIBLE, I WAS LIKEWISE ABLE TO USE EXTRACTED DATA IN MS ACCESS. ALLOWING ME TO BE ABLE TO DO QUERIES, COST ESTIMATES, GROUP ITEMS BY CHARACTERISTICS, APPEND CHANGES TO TABLES OR MOVE ITEMS TO OTHER TABLES, TO BE ABLE TO TRACK THE B.O.M. AND EVERY SINGLE PART FOR MANUFACTURING. MAKING PROJECT MANAGEMENT SIMPLIFIED. THIS SIMPLIFIED CREATING REPETITIVE DOCUMENTATION AND IMPROVED PRODUCTION TRACKING. I WAS INTERIM PRODUCT ENGINEER, MORE PRECISE THAN ANYONE, USING MY TECHNIQUES.

I WAS THEN ABLE TO PROGRAM USING VBA IN MS ACCESS IN ORDER TO BE ABLE TO AUTOMATE THESE REPORTS AND QUERIES THUS I HAD A PROGRAM THAT AUTOMATED TRACKING AND REPORTING OF CONTROL PANEL MANUFACTURING.

FUTURE DEVELOPMENT

Position: DATA-SOLID WORKS

THE DEVELOPMENT OF THIS WAS INTERRUPTED BY THE DESIRE TO USE VENDOR AND CONTRACTOR DRAWING IN AUTOCAD. MANY NOW WANT TO USE SOLID WORKS.

I AM NOT TAKING SIDES IN THIS COMMERCIAL WAR.

I CAN WORK IN IT ALL- WHILE I HAVE ENGINEERING SKILLS AS WELL. I AM NOT JUST DRAWING- I AM PROGRAMMING. A SKILL THAT REQUIRES MY DETRACTORS TO "LEARN", OR COPY FROM SOMEONES EXISTING WORK.

I AM NOT TAKING SIDES IN THIS COMMERCIAL WAR.

I CAN WORK IN IT ALL- WHILE I HAVE ENGINEERING SKILLS AS WELL. I AM NOT JUST DRAWING- I AM PROGRAMMING. A SKILL THAT REQUIRES MY DETRACTORS TO "LEARN", OR COPY FROM SOMEONES EXISTING WORK.