MECHANICAL

COMPANY: VARIOUS

DIVISION: CAD DESIGN

SEGMENT: MECHANICAL DESIGN

SERVICE: MECHANICAL DRAFTING

CUSTOMERS: VARIOUS

DATE: 1993-1996

MECHANICAL DRAFTING

MECHANICAL DESIGN

I HAVE PERFORMED MECHANICAL DESIGN AND DRAFTING FOR VARIOUS COMPANIES. THIS DEMO CONTAINS A PLATFORM I HAD TO MEASURE AND CREATE DRAWINGS. PLATFORM WAS EXISTING SO I HAD TO DO SOME MEASUREMENTS UPSIDE DOWN. I DID MECHANICAL DRAFTING OF SHOP DRAWINGS. AND ALSO MECHANICAL DESIGN TO MODIFY AN EXISTING PART. I HAVE DONE DESIGN OF STRUCTURES AND SUPPORT MEMBERS, BUT DO NOT HAVE THOSE COPIES OF THOSE DRAWINGS TO SHOW.

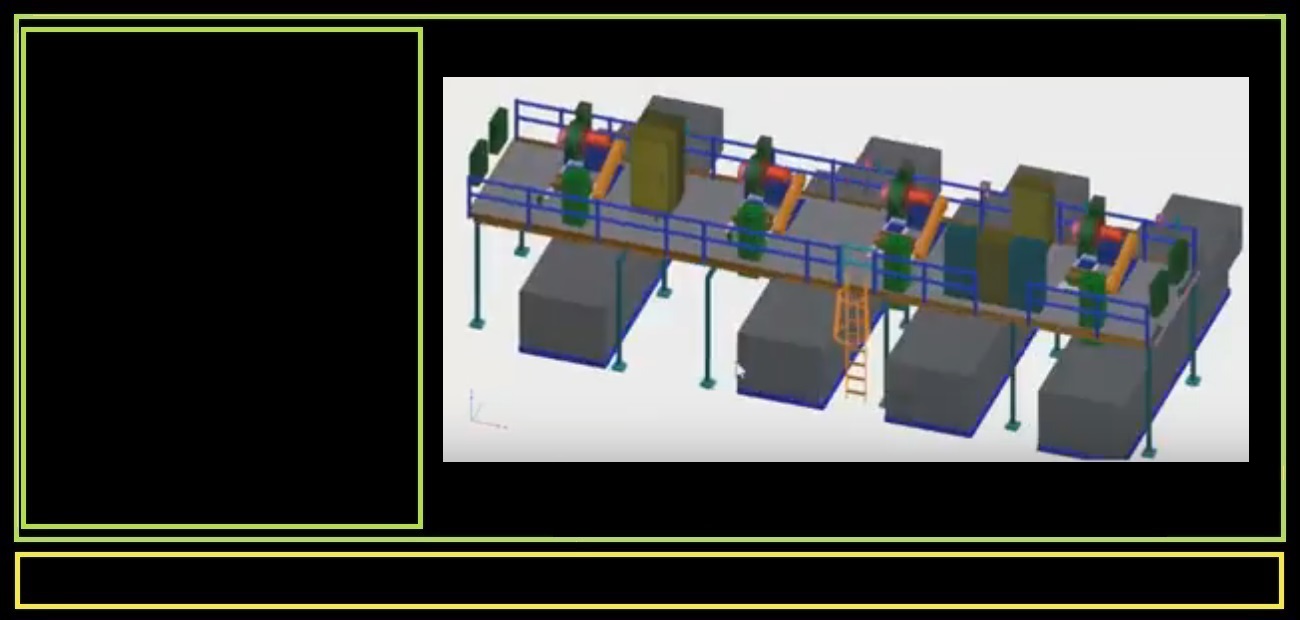

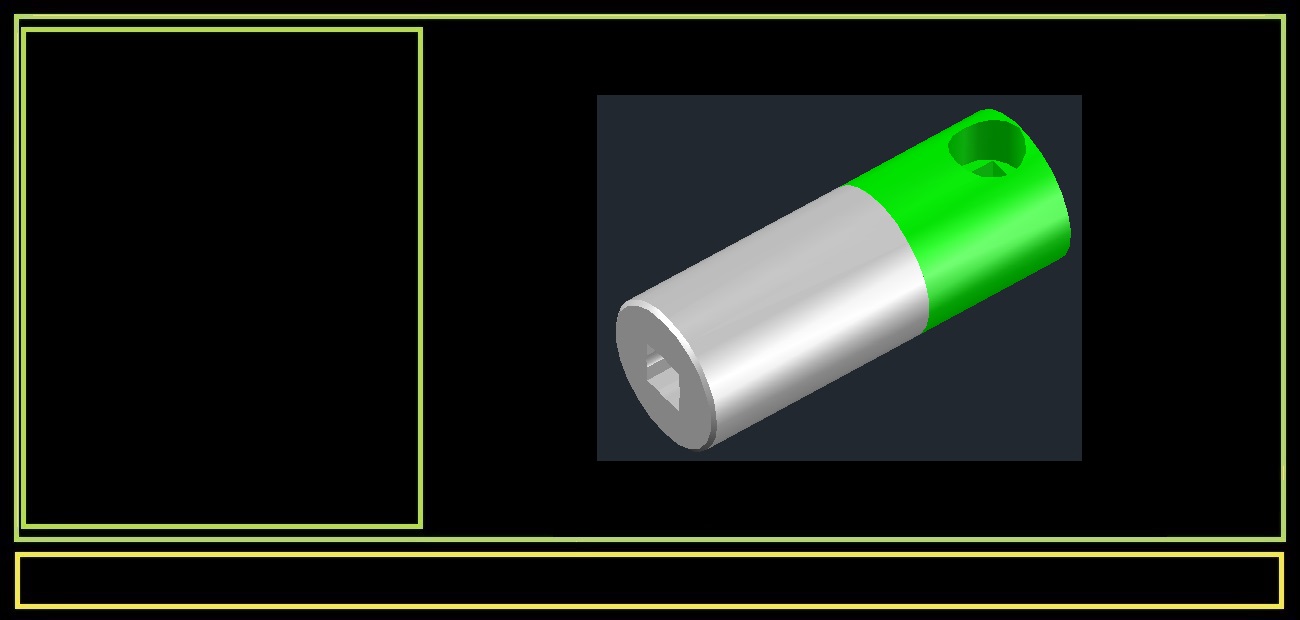

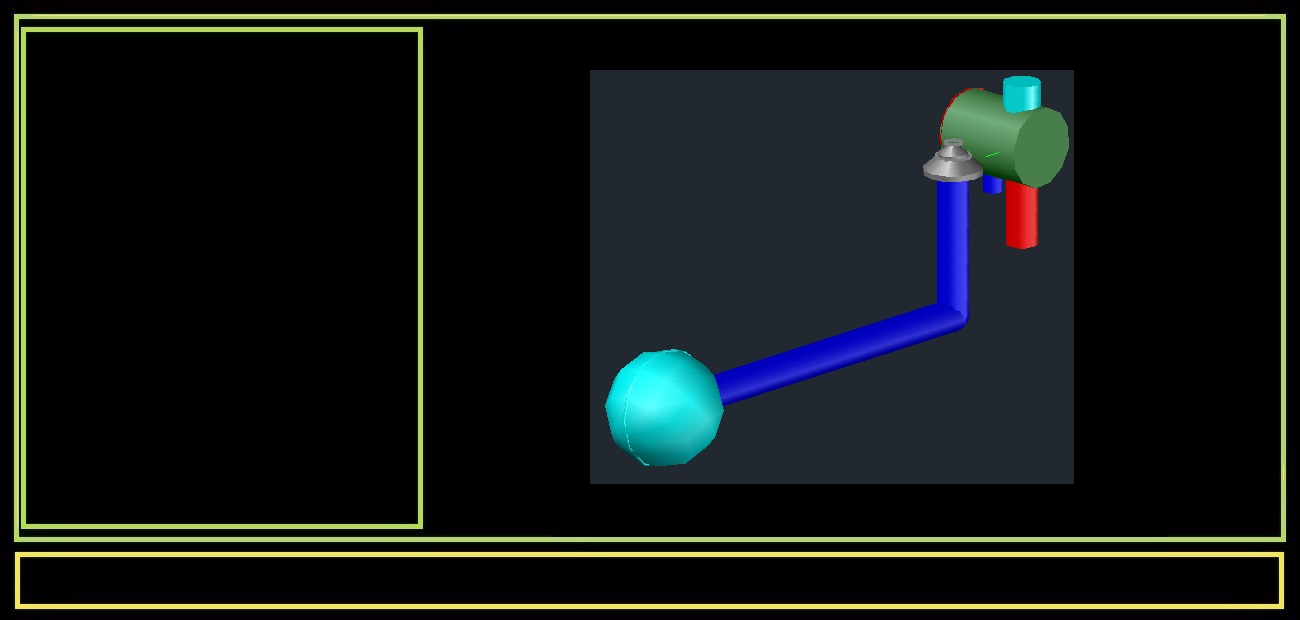

HERE IS A 3D MODEL I CREATED .

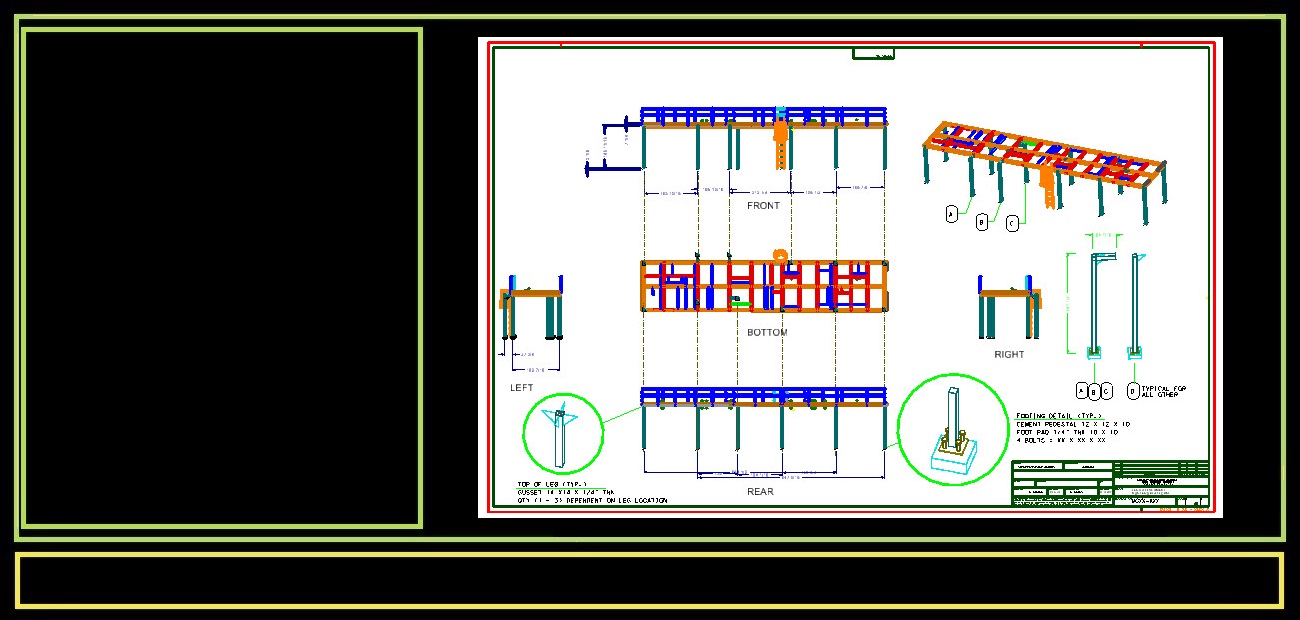

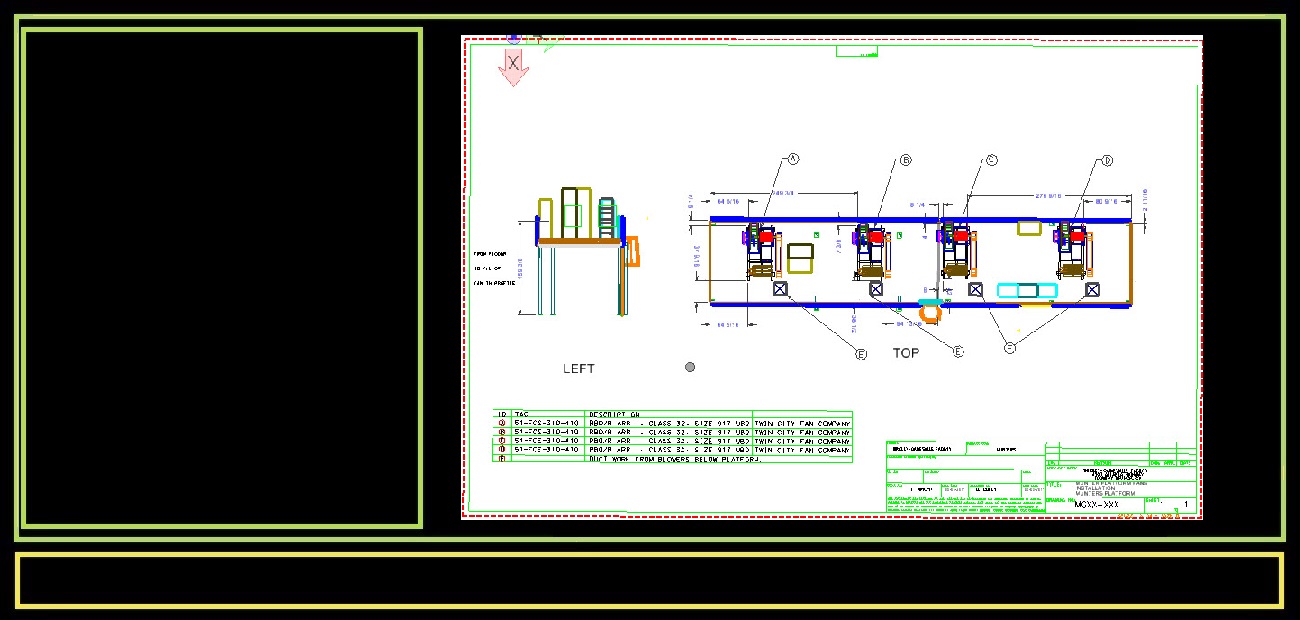

DRAWINGS WERE NEEDED FOR AN OUTSIDE CONTRACTOR TO DO A VIBRATION STUDY AND STRUCTURAL ASSEMENT OF AN EXISTING PLATFORM FOR MODIFICATION.

DRAWINGS WERE NEEDED FOR AN OUTSIDE CONTRACTOR TO DO A VIBRATION STUDY AND STRUCTURAL ASSEMENT OF AN EXISTING PLATFORM FOR MODIFICATION.

THIS IS THE PLATFORM FRAME. I HAD TO MEASURE THE PLATFORM AND EACH MEMBER USED TO FORM THE STRUCTURE ,IN ORDER TO CREATE A MECHANICAL DRAWING WITH DIMENSIONS TO BEGIN DOCUMENTING THE DESIGN.

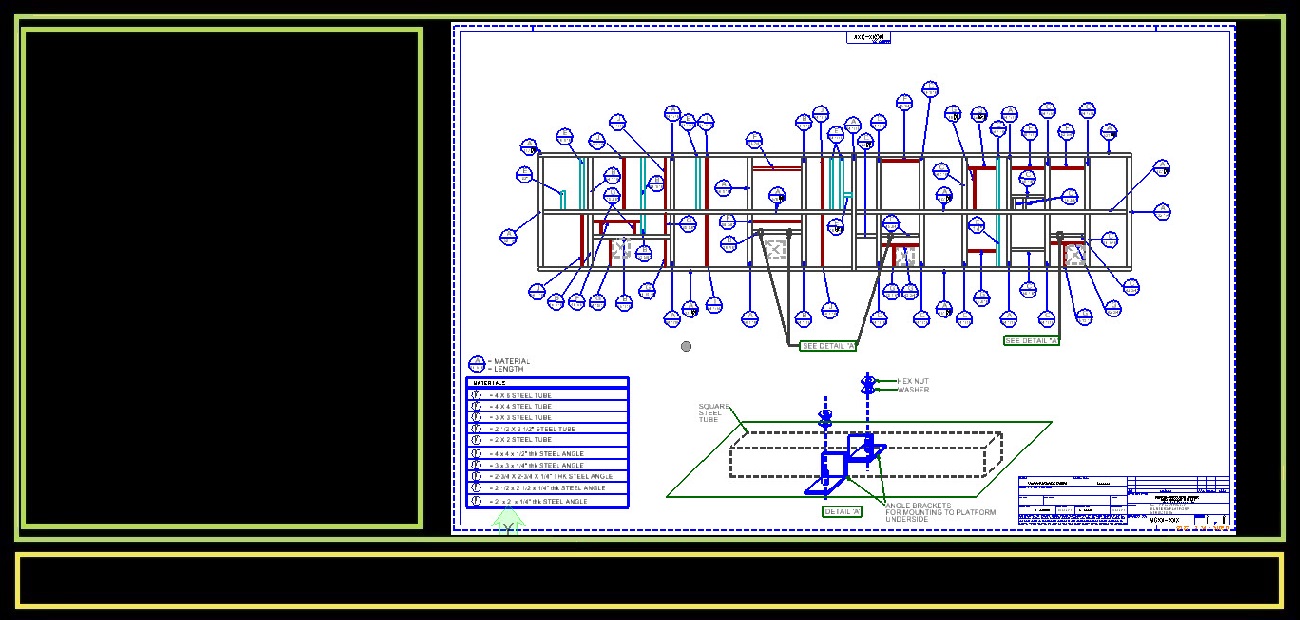

NEXT CREATE A DRAWING OF THE SUPPORT MEMBERS WHICH GAVE THE PLATFORM STRENGTH. SUPPORTS WERE INSTALLED IN "NON-UNIFORM" MANNER IN ORDER TO SUPPLY SUPPORT IN SPECIFIC AREAS.

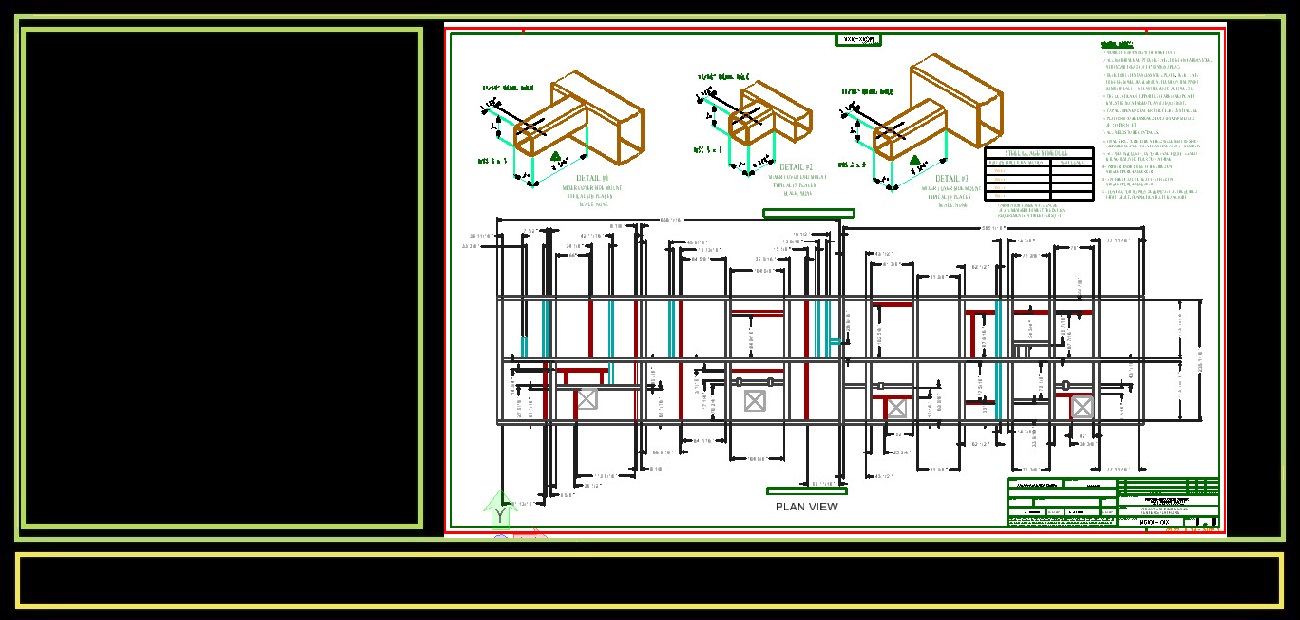

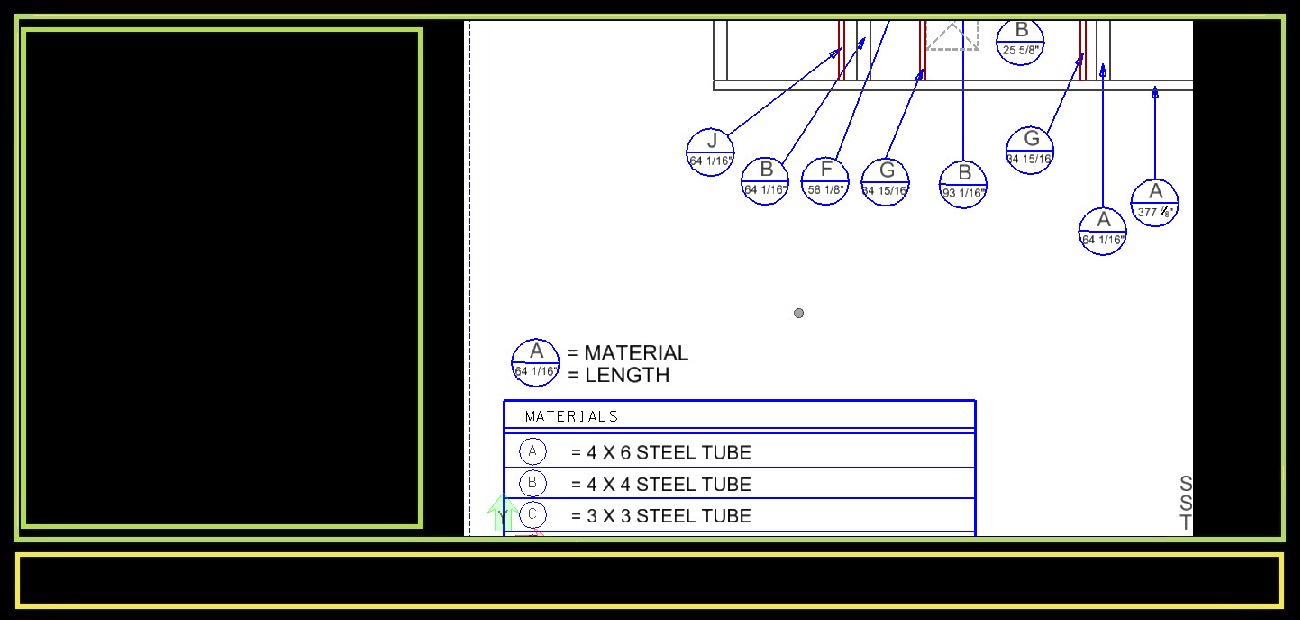

NEXT IT WAS NECESSARY TO SHOW THE INDIVIDUAL SIZES AND TYPES OF SUPPORT BEAM. I CREATED A TABLE TO DEFINE THE SHAPES AND LENGTHS OF EACH SUPPORT, FOR A CLEANER DRAWING. EACH ITEM BUBBLE RELATES TO THAT TABLE.

HERE IS A CLOSEUP. EACH ITEM "CALLOUT BUBBLE" IS DEFINED BY THIS CHART. THE CHART SHOWED BEAM DIMENSIONS WHILE THE BUBBLES SHOWED THE INDIVIDUAL LENGTHS FOR AN ORGANIZED DRAWING.

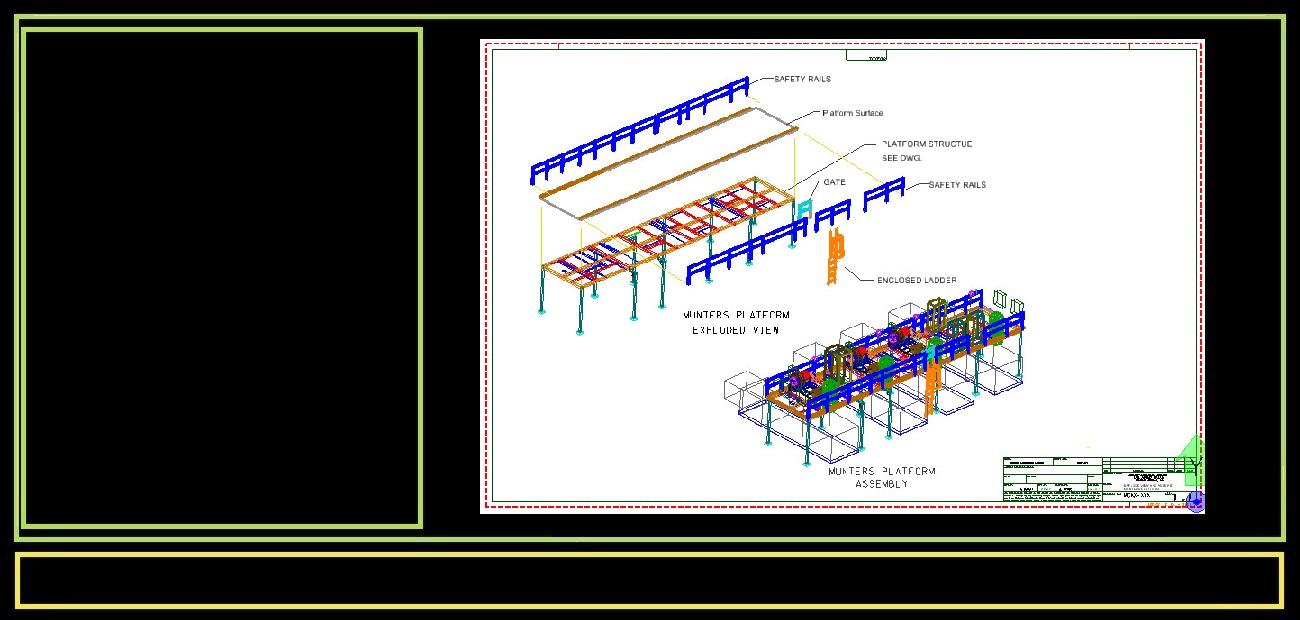

HERE IS AN "EXPLODED VIEW" TO DEFINE THE ARRANGEMENT AND ASSEMBLY OF ASSOCIATED PARTS. THIS INCLUDED HAND RAILS, THE FRAME, THE PLATFORM FLOOR, AND ACCESS LADDER.

ALSO A VIEW OF HOW THE PLATFORM SITS OVER THE EXISTING EQUIPMENT.

ALSO A VIEW OF HOW THE PLATFORM SITS OVER THE EXISTING EQUIPMENT.

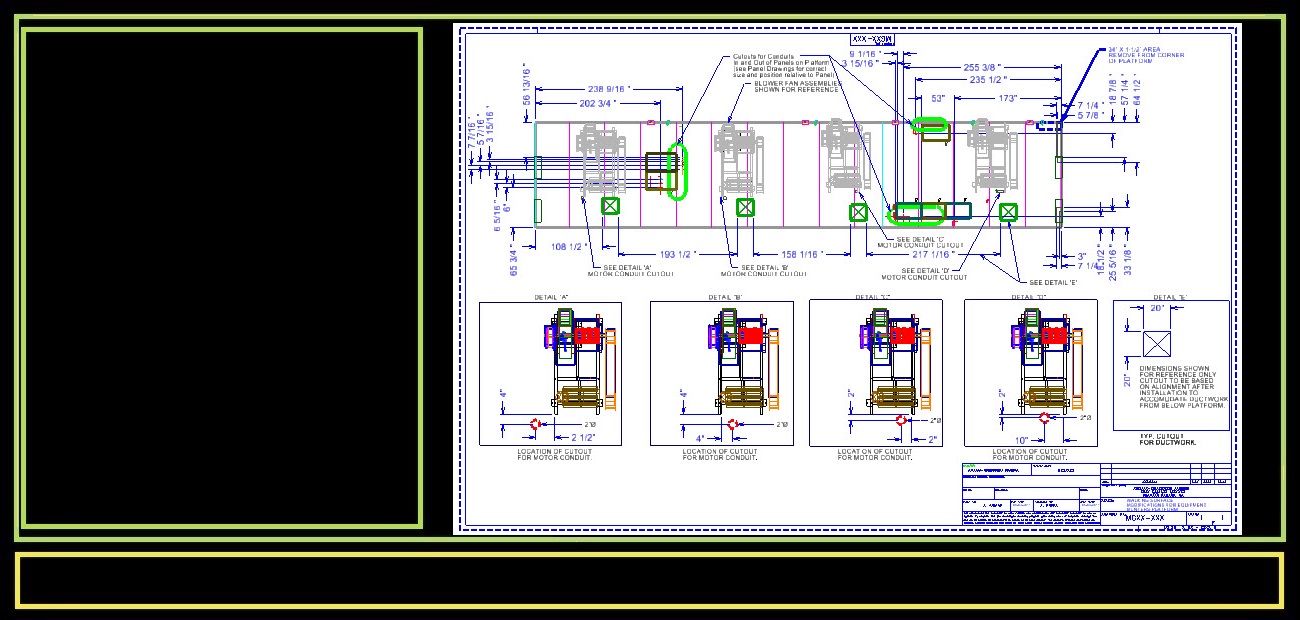

TO ALLOW FOR DUCTS AND CONDUITS THERE WERE "CUTOUTS" IN THE PLATFORM FLOOR. THIS SHOWS(SIZES AND PLACEMENT WITH DIMENSIONS). ALSO BLOWERS NEED TO BE MOUNTED AS WELL SO I HAD TO MEASURE AND DETERMINE EQUIPMENT MOUNTING LOCATIONS.

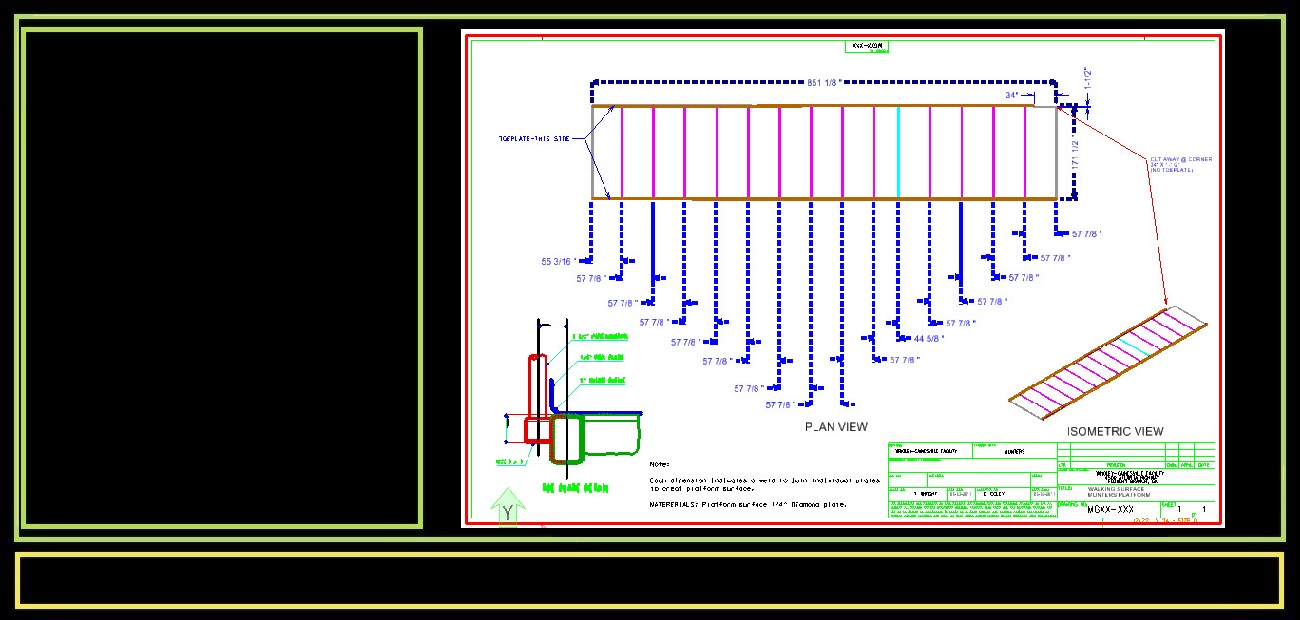

THE PLATFORM FLOOR WAS NOT ONE SOLID PIECE, BUT WAS CONSTRUCTED FROM MULTIPLE SHEETS OF ALUMINUM PANELS. I THEN HAD TO MEASURE EACH PANEL AND SHOW WELDINGS TO ASSEMBLE THE PLATFORM.

A DRAWING ALSO HAD TO BE MADE OF THE MOUNTING OF THE EQUIPMENT AND DIMENSIONS ON THE PLATFORM TO DETERMINE WEIGHT REQUIREMENTS. MAKING IT EASIER FOR THE CONTRACTOR TO CONDUCT VIBRATION ANALYSIS.

"DRAFTING".

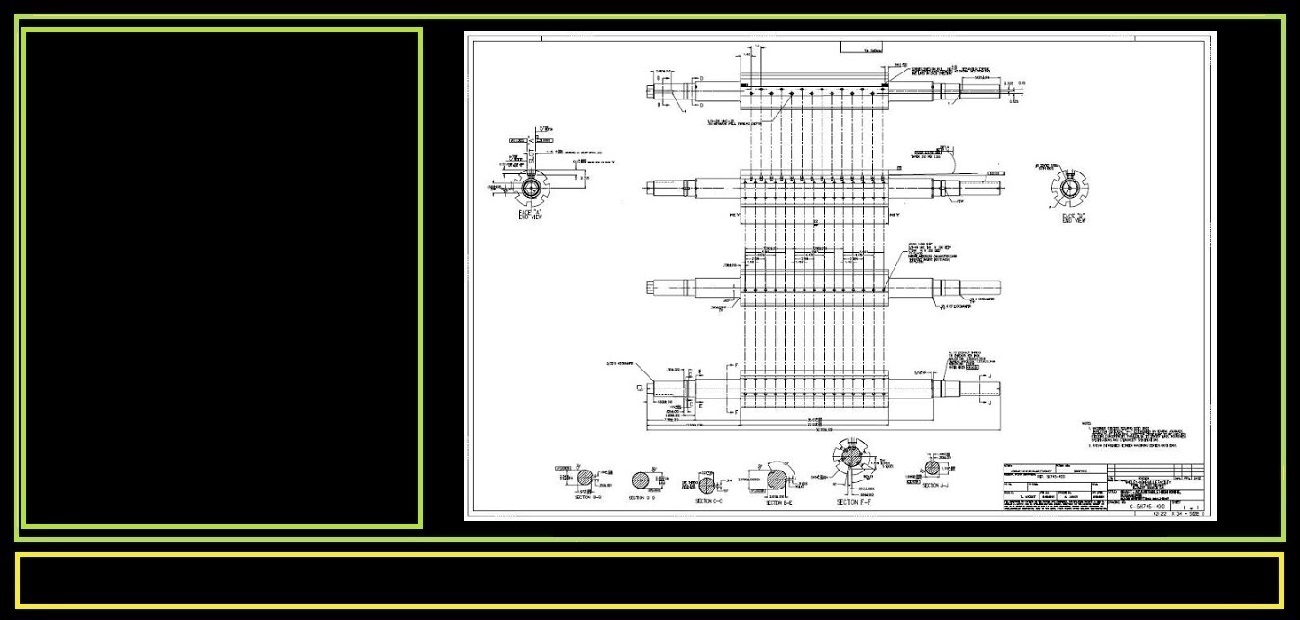

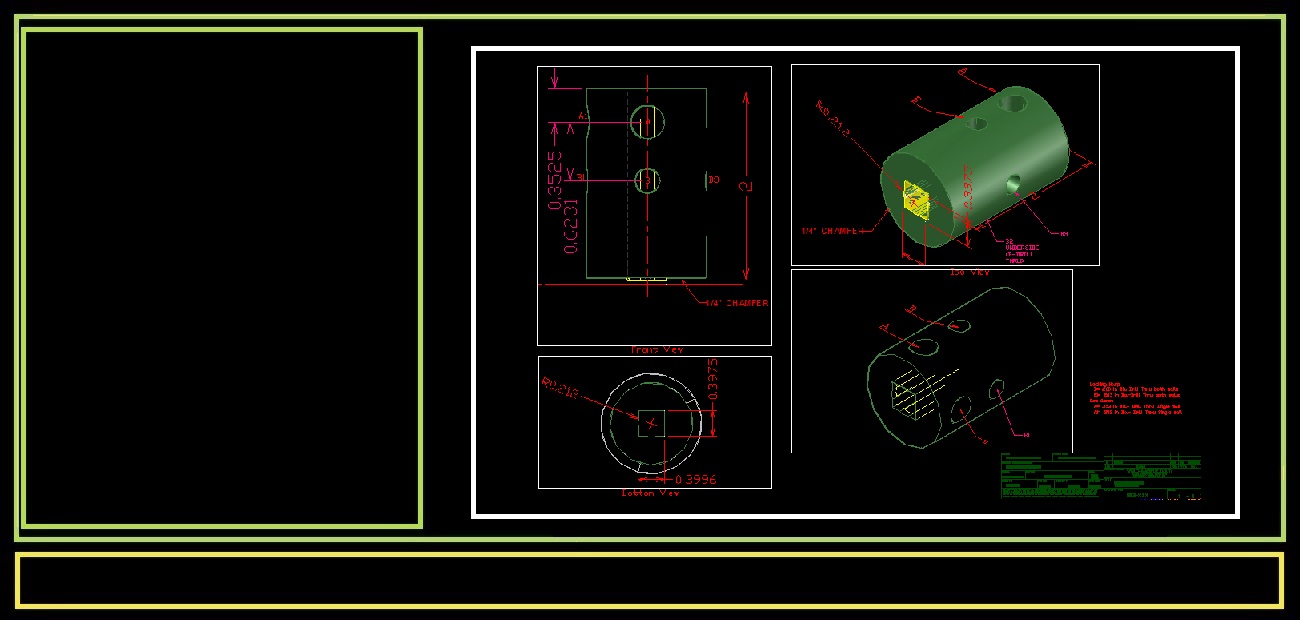

I WAS ASKED TO CREATE A DRAWING OF A MIXER SHAFT BECAUSE THERE WAS NO EXISTING DRAWINGS. I USED CALIPERS TO MEASURE AND CREATE THE DRAWING SO IT COULD BE SENT OUT FOR MANUFACTURE. AN ERROR WOULD BE EXPENSIVE.

I WAS ASKED TO CREATE A DRAWING OF A MIXER SHAFT BECAUSE THERE WAS NO EXISTING DRAWINGS. I USED CALIPERS TO MEASURE AND CREATE THE DRAWING SO IT COULD BE SENT OUT FOR MANUFACTURE. AN ERROR WOULD BE EXPENSIVE.

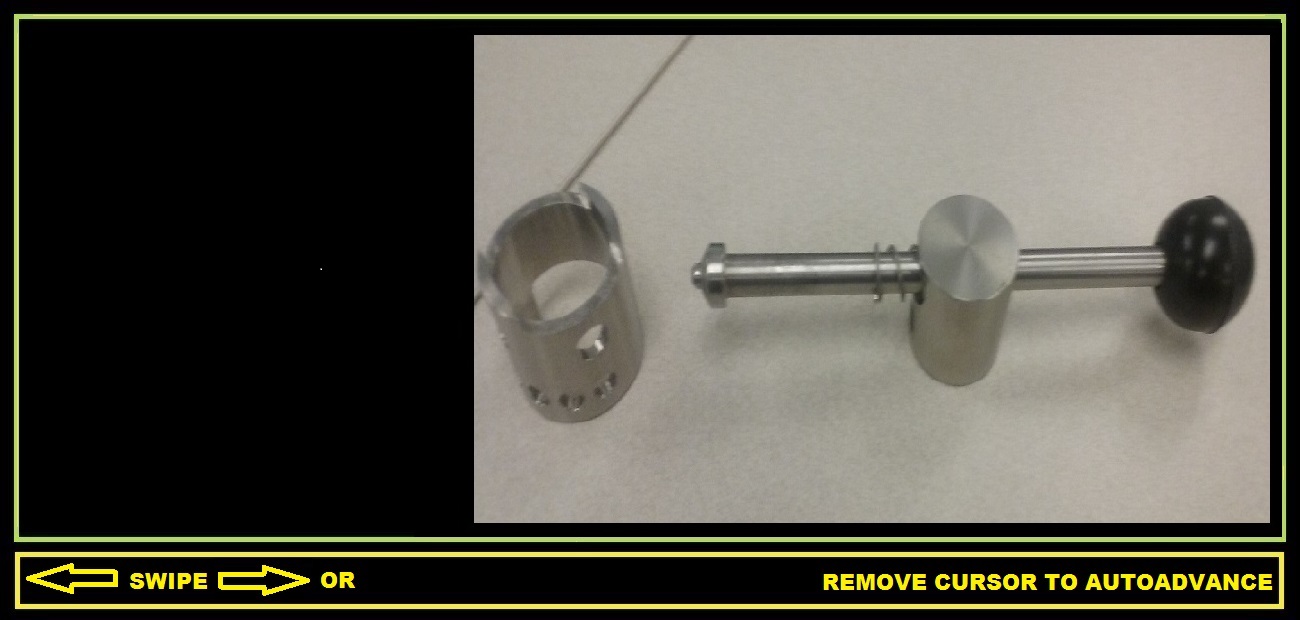

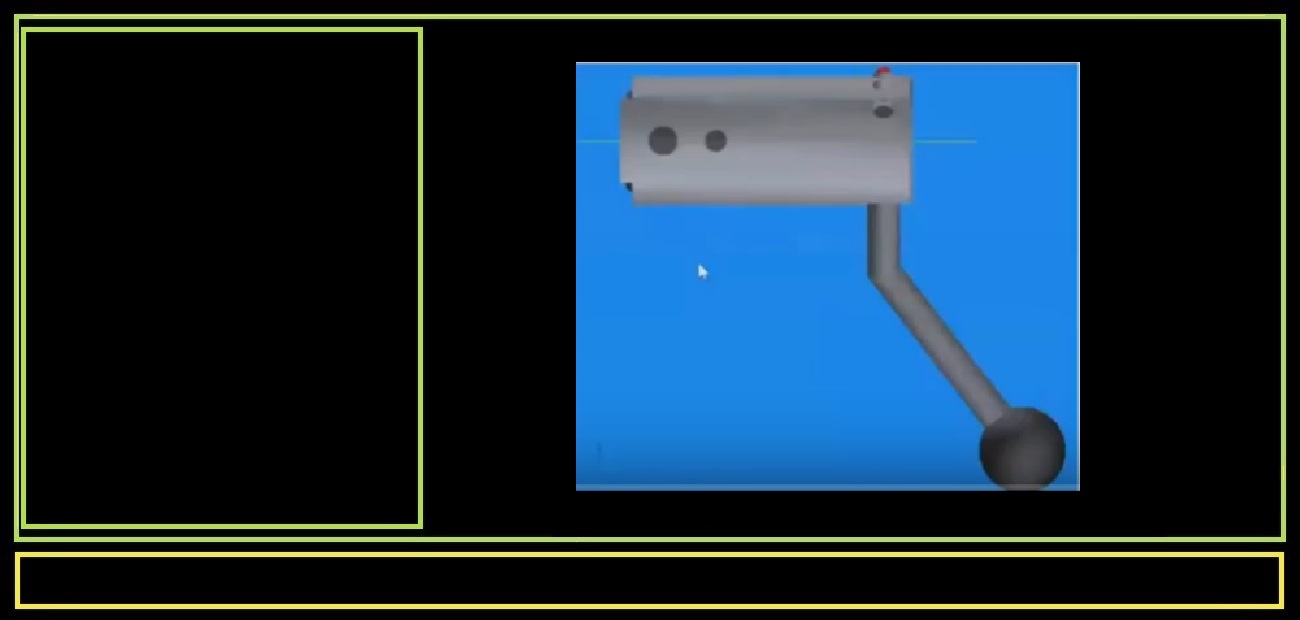

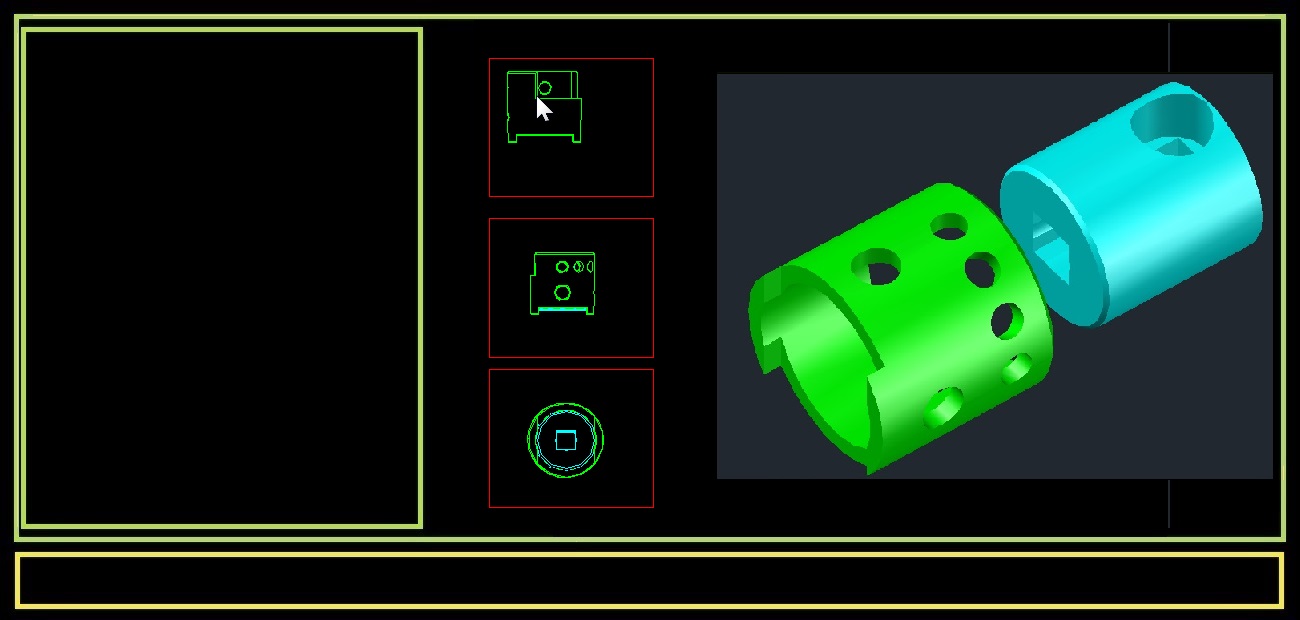

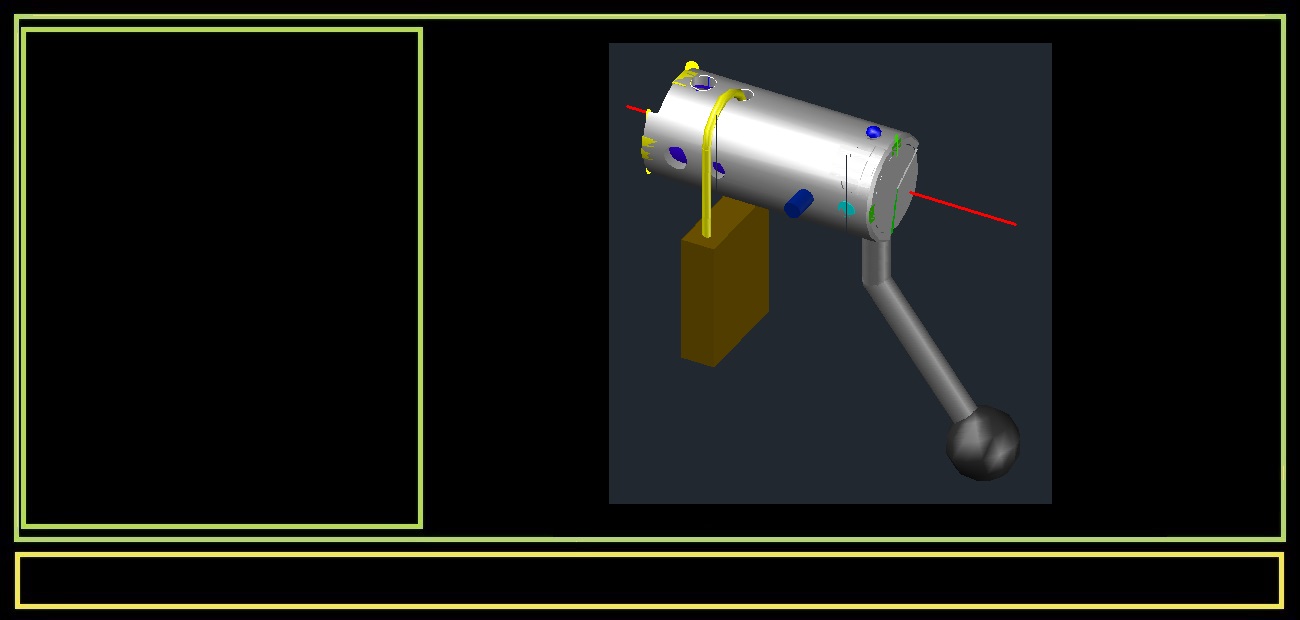

ON THE RIGHT IS A "MIXER HANDLE". THIS WAS A "PART DESIGN" TASK.

"PART DESIGN":

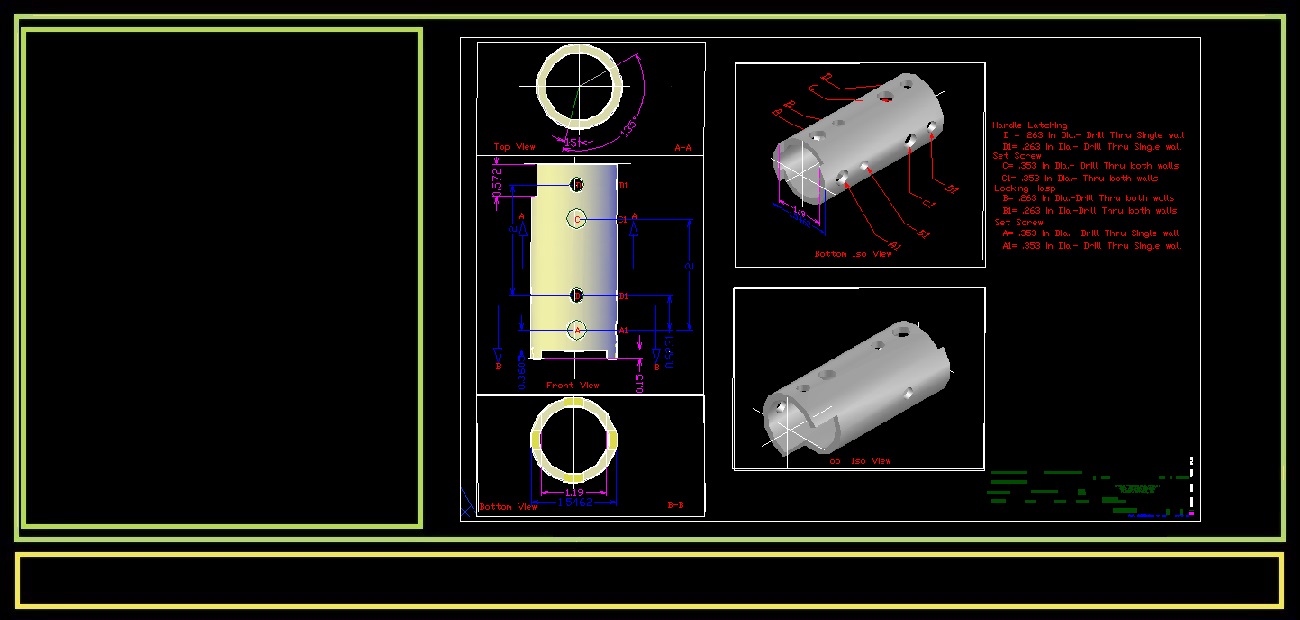

THE EXSITING HANDLE WAS TOO SHORT . IT HAD HOLES THAT HAD TO MATE FOR CORRECT OPERATION. ADDITIONAL HOLES WERE NEEDED TO BE ADDED, IN ORDER TO ADD A METHOD TO THE LOCK THE HANDLE IN PLACE.

THE EXSITING HANDLE WAS TOO SHORT . IT HAD HOLES THAT HAD TO MATE FOR CORRECT OPERATION. ADDITIONAL HOLES WERE NEEDED TO BE ADDED, IN ORDER TO ADD A METHOD TO THE LOCK THE HANDLE IN PLACE.

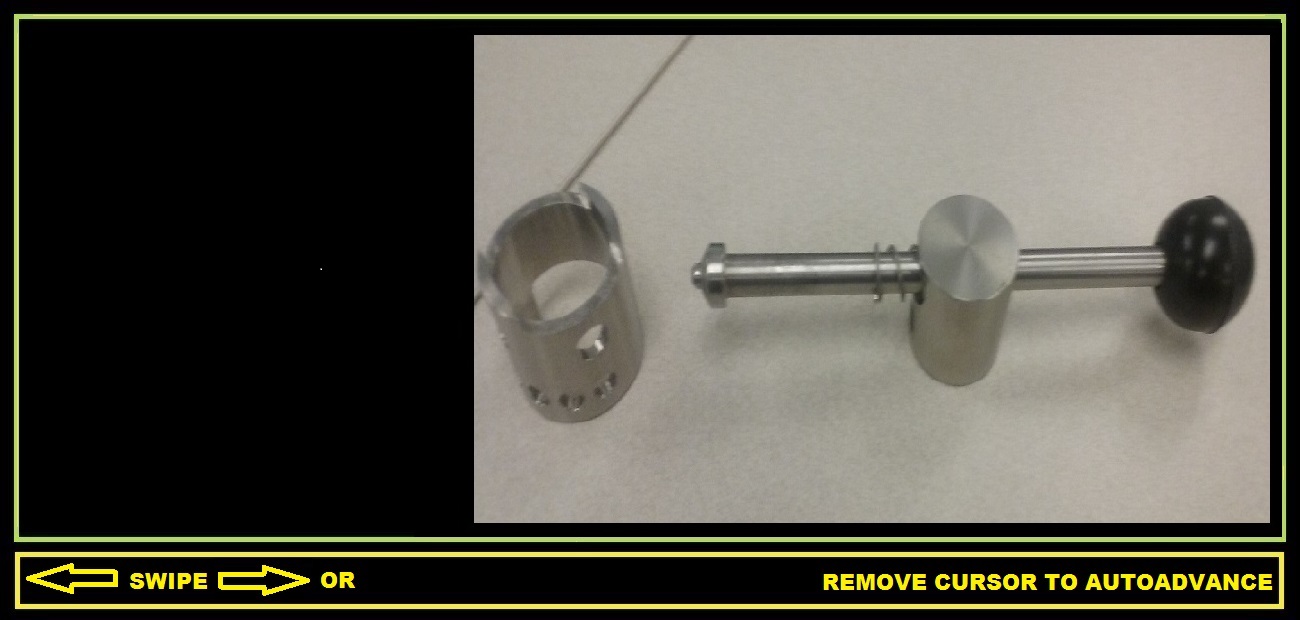

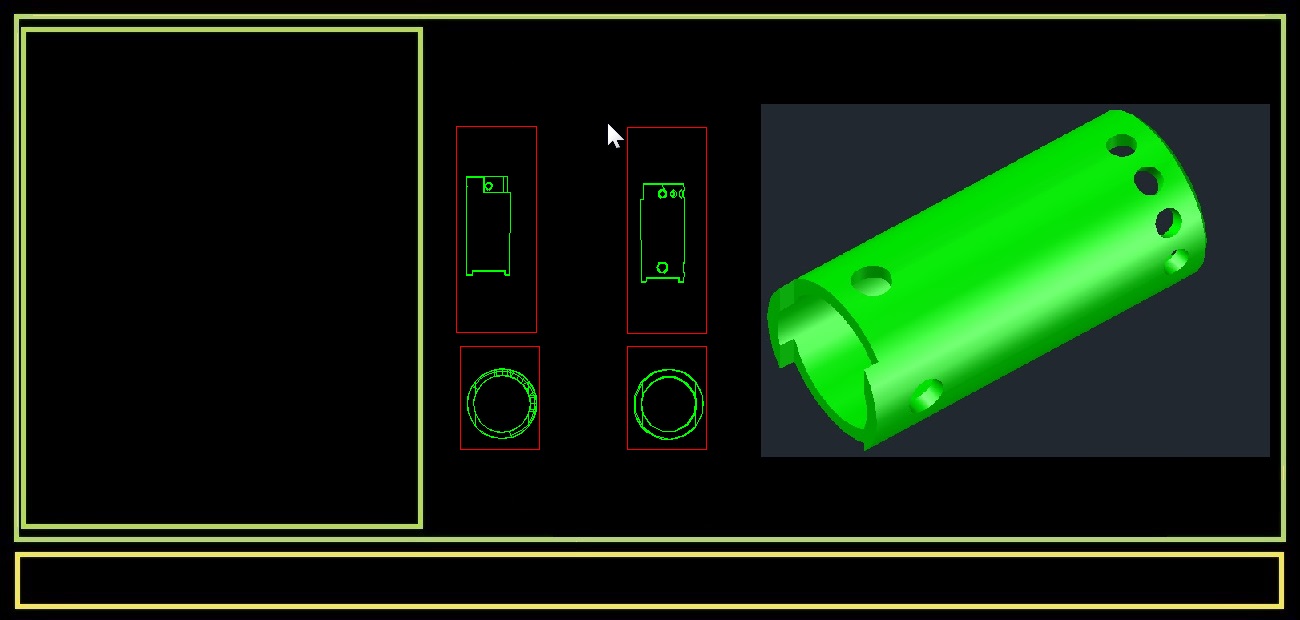

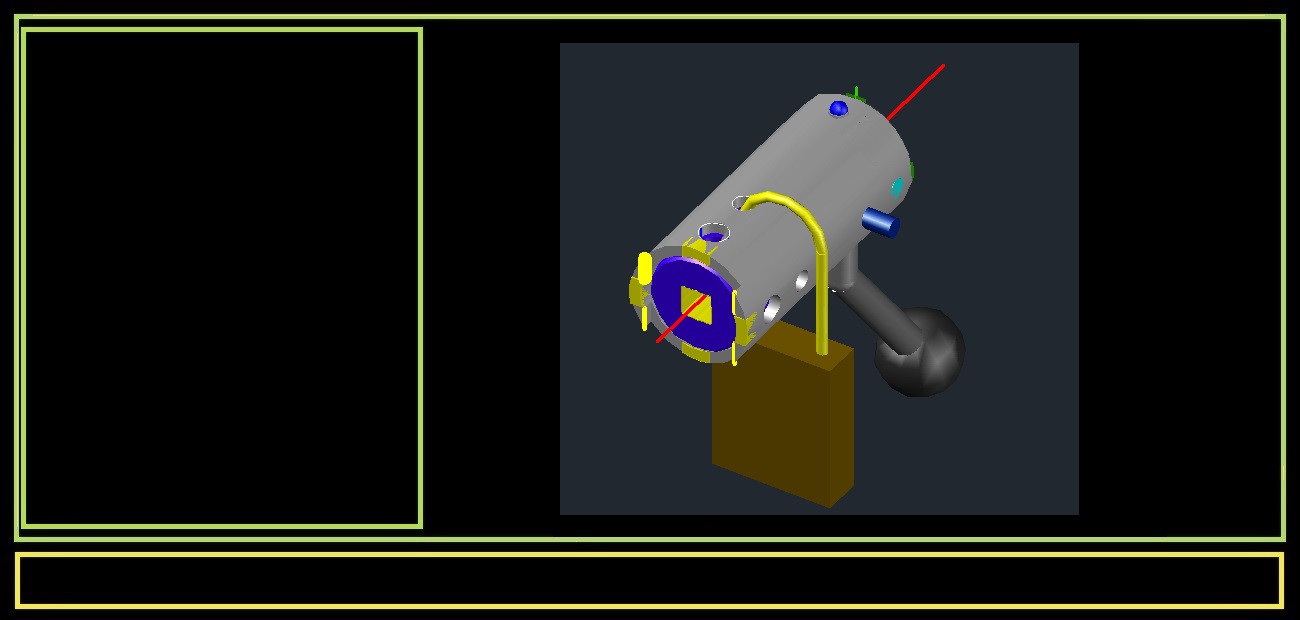

HERE ARE THE TWO PARTS . A SMALL INNER SHAFT AND A OUTER SLEEVE WITH HOLES WHICH MUST ALIGN. "2D VIEWS" AND A "3D MODEL".

THE SLIDE HAD TO FIT WITHIN THE SLEEVE AND HOLES FOR ASSEMBLY HAD TO ALIGN. SO TOLERANCES NEEDED TO BE EXACT. ELSE THE HANDLE WOULD NOT FUNCTION CORRECTLY.

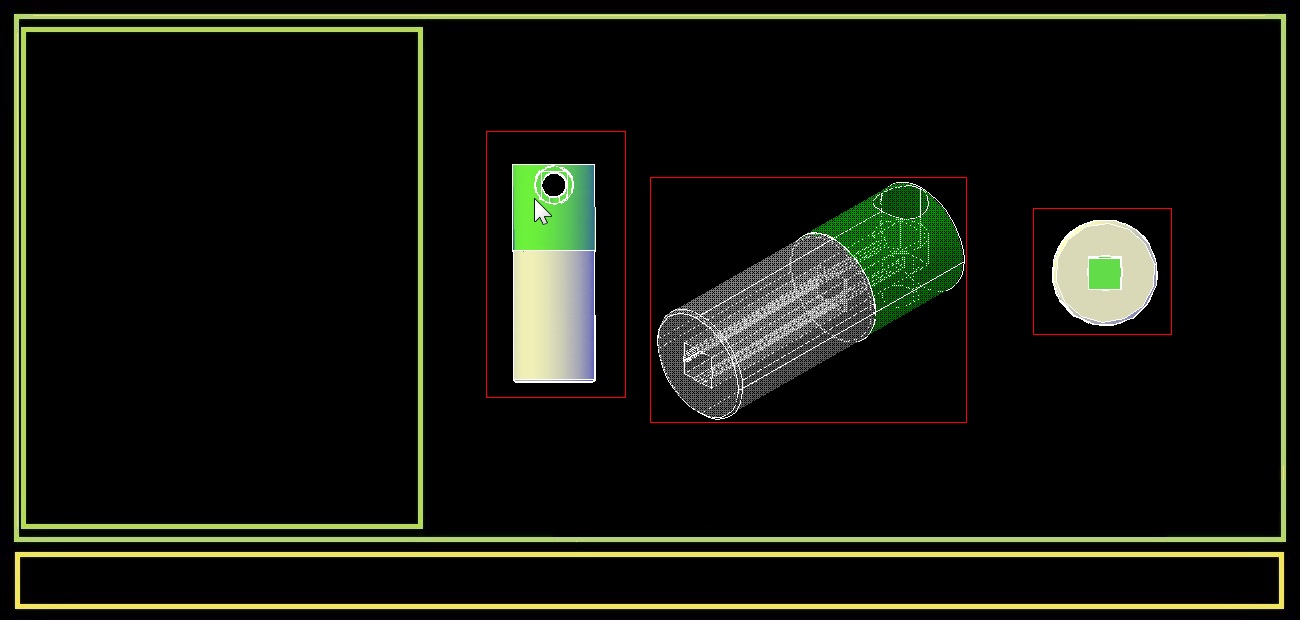

THE NEW GREY PIECE IS "AN EXTENTION" I DESIGNED TO EXTEND THE PIECE TO THE CORRECT LENGTH. A MATING KEYHOLE CUTOUT WAS NEEDED TO EXTEND THE CENTRAL SHAFT TO ACCOMODATE THE MIXERS SHAFT TO ATTACH THE HANDLE TO THE MACHINE.

I DESIGNED THE EXTENDED SLIDE FOR THE PRODUCTION SHOP TO FABRICATE. MAKING SURE TO MATCH THE MATING HOLES IN A NEW LOCATION.

THIS SHOWS THE EXTENDED "SLIDE".

THE ORIGINAL COULD NOT SIMPLY BE EXTENDED.I MEASURED HOLES AND DESIGNED A NEW SLEEVE. AND SENT THE DRAWINGS TO THE "SHOP" FOR FABRICATION.

I LOCATED HOLES TO MATE THE TWO PIECES PROPERLY. THIS SHOWS THE MODIFIED SLEEVE.

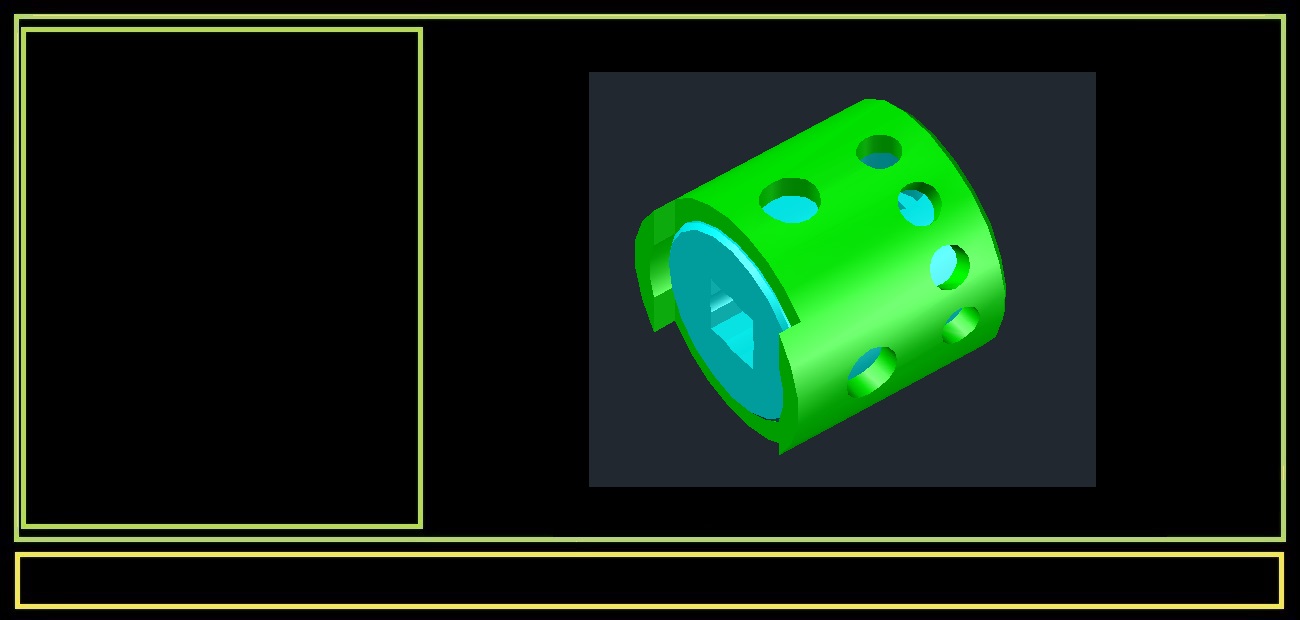

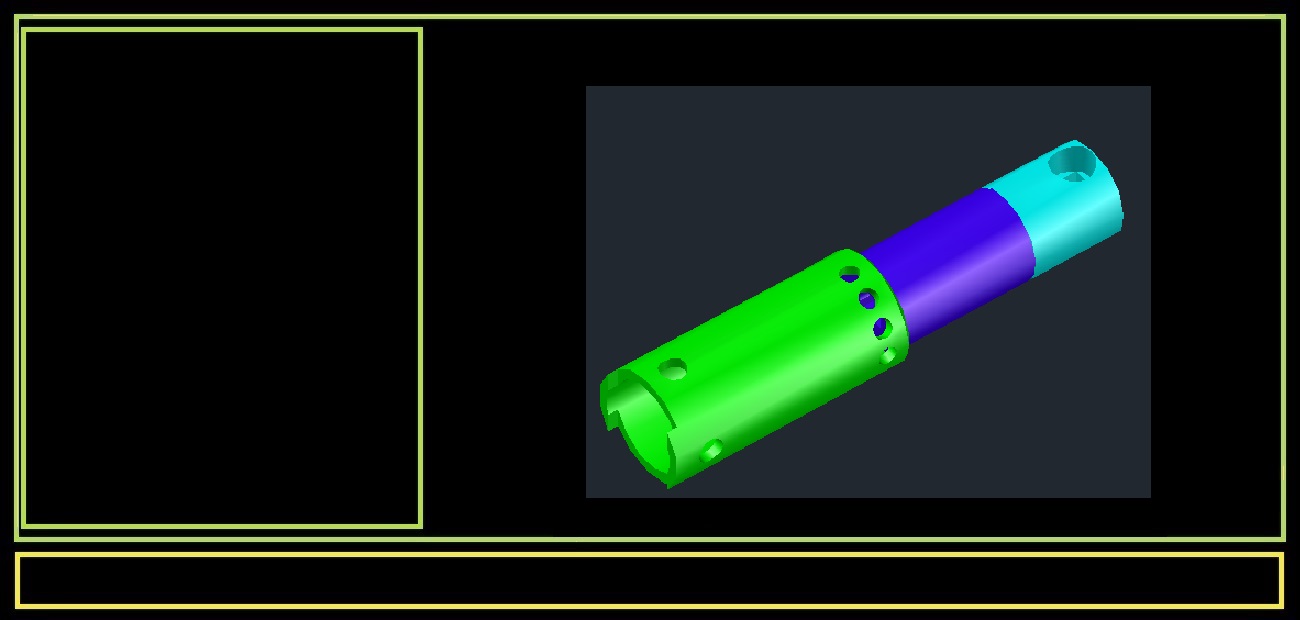

NEXT IS A IMAGE OF HOW THE TWO PIECES ARE TO BE INSERTED AND MATED TO EACH OTHER. TO ASSURE MEETING THE INTERACTION BETWEEN BOTH NEW PARTS.

THE EXISTING HANDLE WAS A STRAIGHT PIECE. TO BE ERGONOMIC, I ASKED THE SHOP TO BEND ONE TO A NEW ANGLE AND THEN DRAFTED THE DIMENSIONS, IN ORDER TO CREATE NEW ONES IN THE FUTURE

THE DRAWING / MODEL AT RIGHT WAS TO HELP ME VERIFY THE ASSEMBLY AND HANDLE AND INSERT A LOCK INTO THE NEW HOLES TO ASSURE THE DESIGN WAS CORRECT.

HERE IS A IMAGE OF THE FINAL HANDLE.